DIY designs have been taking the design world by storm! Especially with COVID-19 restricting us to our homes, building things purely with our hands, putting our sweat and grit into it, and watching a design roar to life in front of our eyes, has become the new pass time for many of us. But these DIY designs are more than just your run-of-the-mill products made using discarded water bottles, and paper! These are innovative, complex, and highly functional product designs that cater to a variety of our needs, but are also really simple to put together. It’s the best of both worlds. From a sustainable helmet made from mushroom to DIY NASA-inspired airless bike tires – each of these nifty designs will get your creative juices flowing, your hands moving, as well as definitely add some value to your life. Which of these unique DIY designs would you try building at home?!

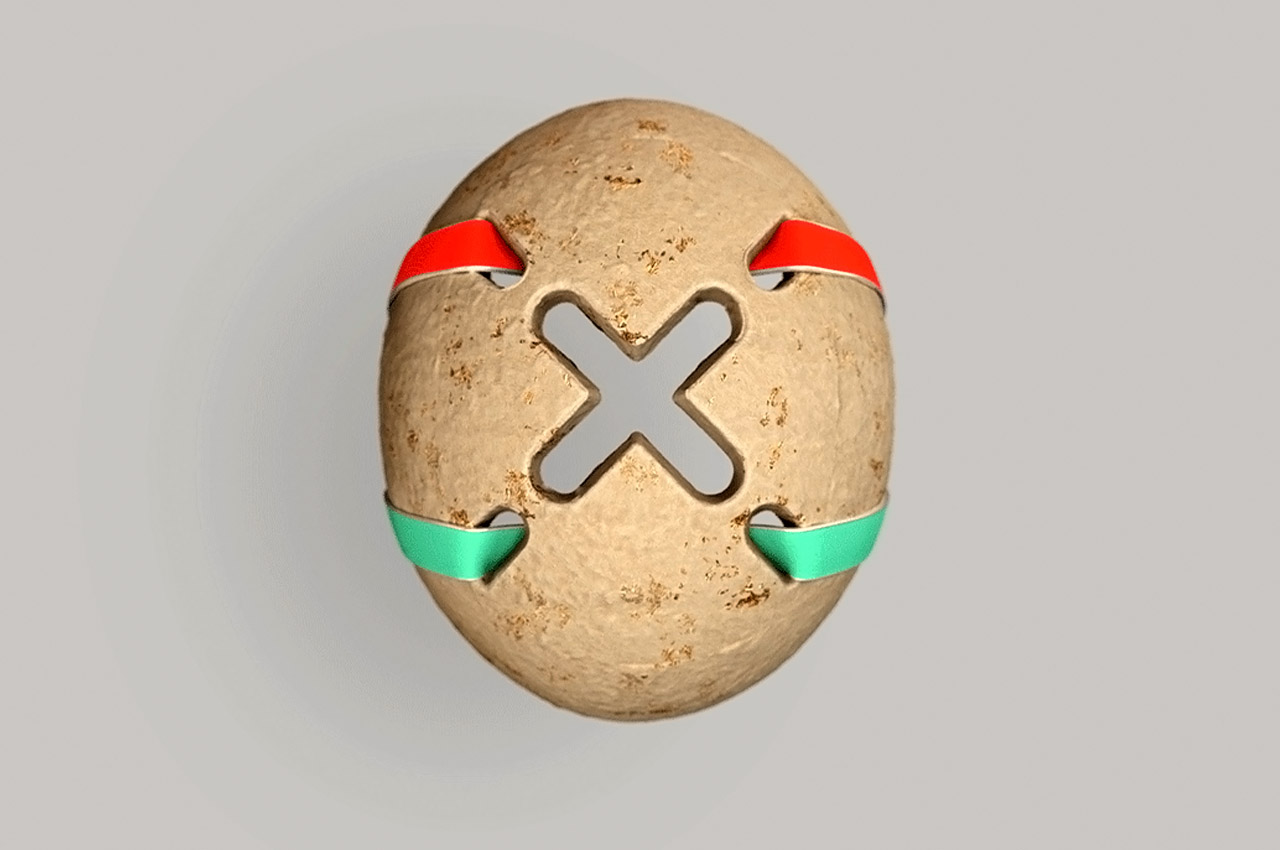

This mushroom helmet will grow on you as it grows. Yes, read this slowly and carefully: this mushroom helmet will grow on you as it grows. “What do you mean?!” you say and I assure you that statement is not wrong, there is an explanation for it. The Grow It Yourself Helmet is a sustainable product made from mycelium which is the vegetative part of a fungus. Mycelium is the thready hyphae that are tightly woven into mass branch-like networks making it a strong sustainable material. The network of filaments are natural binders and they also are self-adhesive to the surface they grow on. The entire process is based on biological elements that help in upcycling waste. The process of making this helmet also gets the kids involved in a meaningful activity that teaches them about sustainability and safety.

No one wants a flat tire while mowing the lawn or playing golf and the chance for a flat tire is far higher in places like construction zones and building demolition sites. It makes sense that some vehicles prioritize airless tires and some don’t, but what about bicycles? The Q, popular science and DIY YouTube channel, asked the same question and looked no further than an old PVC pipe and some nuts and bolts to answer it. Before constructing his airless tires, The Q was sure to pick a PVC pipe that had enough density to support a rider and ride well on different terrain. Settling on a ½” thick PVC pipe, The Q then sliced the PVC pipe into two-inch wide rings. From there, the DIY YouTuber connected all of the rings into a single link after drilling three holes into each and joining them together with nuts and bolts.

The R3 DIY Bluetooth Radio from Celia & Perah audio engineering company allows users to build their own speakers and learn about the magic behind its superb sound quality. For Celia & Perah, weaving in the DIY aspect of R3 provided the speaker with a bit more meaning. When someone buys an R3 Bluetooth Speaker, they’re also buying the experience of building their own music-making device and learning more about “the acoustic magic behind the [speaker’s] superb sound quality,” as Celia & Perah put it. R3 is a DIY Bluetooth speaker that can be built within an hour and customized to fit your taste. Users can even spraypaint it a certain color to match the tone of any given room.

Now available for shipping in the US, VanLab’s flatpack van conversion kits require only two electric screwdrivers and can be assembled inside your van between three and six hours, then all that’s left to do is configure the wiring. Like IKEA furniture, VanLab’s conversion kits can be built by anyone; no carpentry experience is necessary. Speaking to the ease of assembly, VanLab founders note, “Absolutely anyone can build this kit. All the holes are pre-drilled and the panels are pre-cut. All you need to do is follow the simple instructions in the manual provided and screw the panels together.” Constructed from Baltic Birch plywood, the wooden panels come pre-finished and are designed to fit together like puzzle pieces so anyone can give rise to their van outfittings with ease.

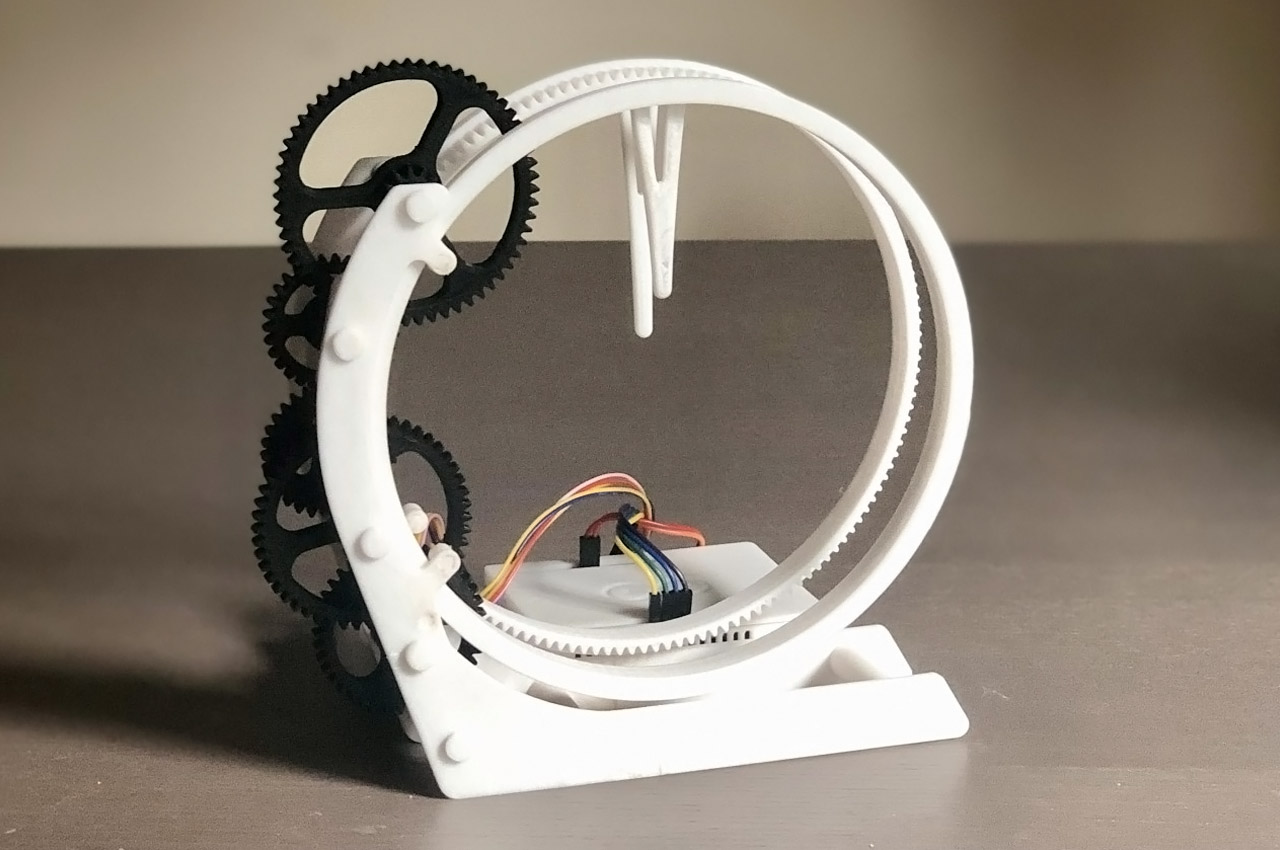

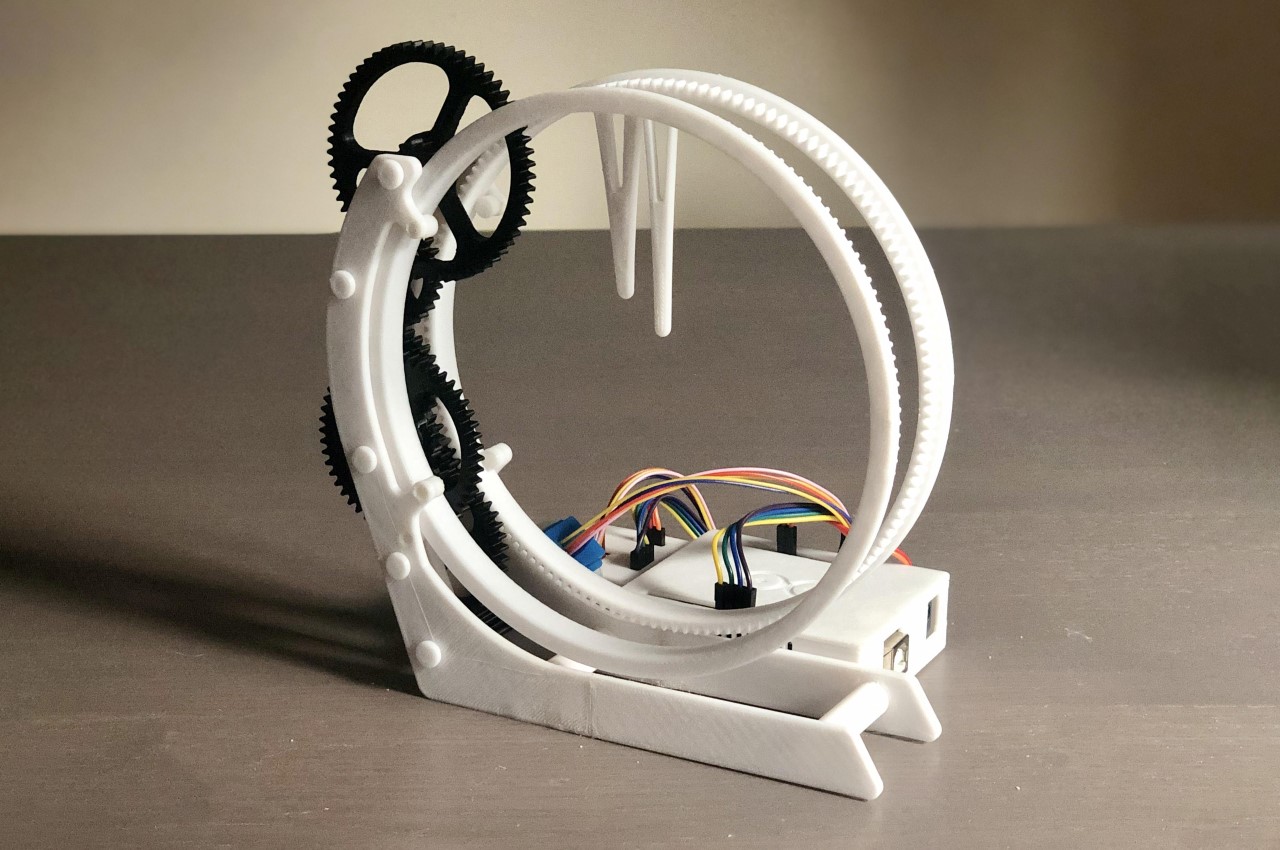

The Holo Clock’s design is characterized by its beautiful hollow design. While traditional clocks use a set of rotating hands pivoted at the center of the clock’s face, the Holo Clock uses a set of rotating rings with hands on them. The rings are controlled by a stepper motor at the bottom of the clock, and the entire clock comes with a flat base, allowing you to keep it on a tabletop surface and admire it ever so often. The designer of the Holo Clock goes by the name of saulemmetquinn, and he’s been gracious enough to document his entire process and make all the CAD parts available on his Instructables page. That, unfortunately, means that the Holo Clock isn’t for sale, although you’re more than welcome to build one of your own. Maybe you could experiment with colors and 3D-printed materials too, to create something even more captivating.

Reza Baluchi has run from Los Angeles to New York City twice and around the perimeter of the United States, accumulating 11,720 miles along the way. With all of this already under his belt, walking from St. Augustine, Florida to New York City over the Atlantic Ocean, not in a boat, but in a DIY floating bubble seemed easy. The floating bubble, dubbed “hydropod,” would have floated Baluchi all the way to the Hudson River’s shoreline if his trek wasn’t cut short some 30 miles south of his launch point. Mr. Baluchi, a former professional cyclist, said that he was hoping to use the attention from his trip to raise money to help homeless people and for other charitable causes. Over the years, he said, he has received puzzled reactions — including from the Coast Guard — after performing similar stunts on the water.

Royole has shown an incredible ability to find the right niche and pivot at the right time with its technological offerings. The company arguably built the first-ever flexible smartphone – the FlexPai – outpacing even Samsung, and their RoKit now aims at helping democratize the fully flexible display (FFD), so creatives and designers can tinker with it, building their own products too. This means you could practically build your own folding smartphone (like how Scotty Allen’s been trying to make his own folding iPhone). Royole’s even showcased an example of what they would make and it looks rather impressive. A baton-shaped device with a rolled-up on the inside and a massive camera facing outwards. Sort of like unscrolling a parchment, the display rolls outwards.

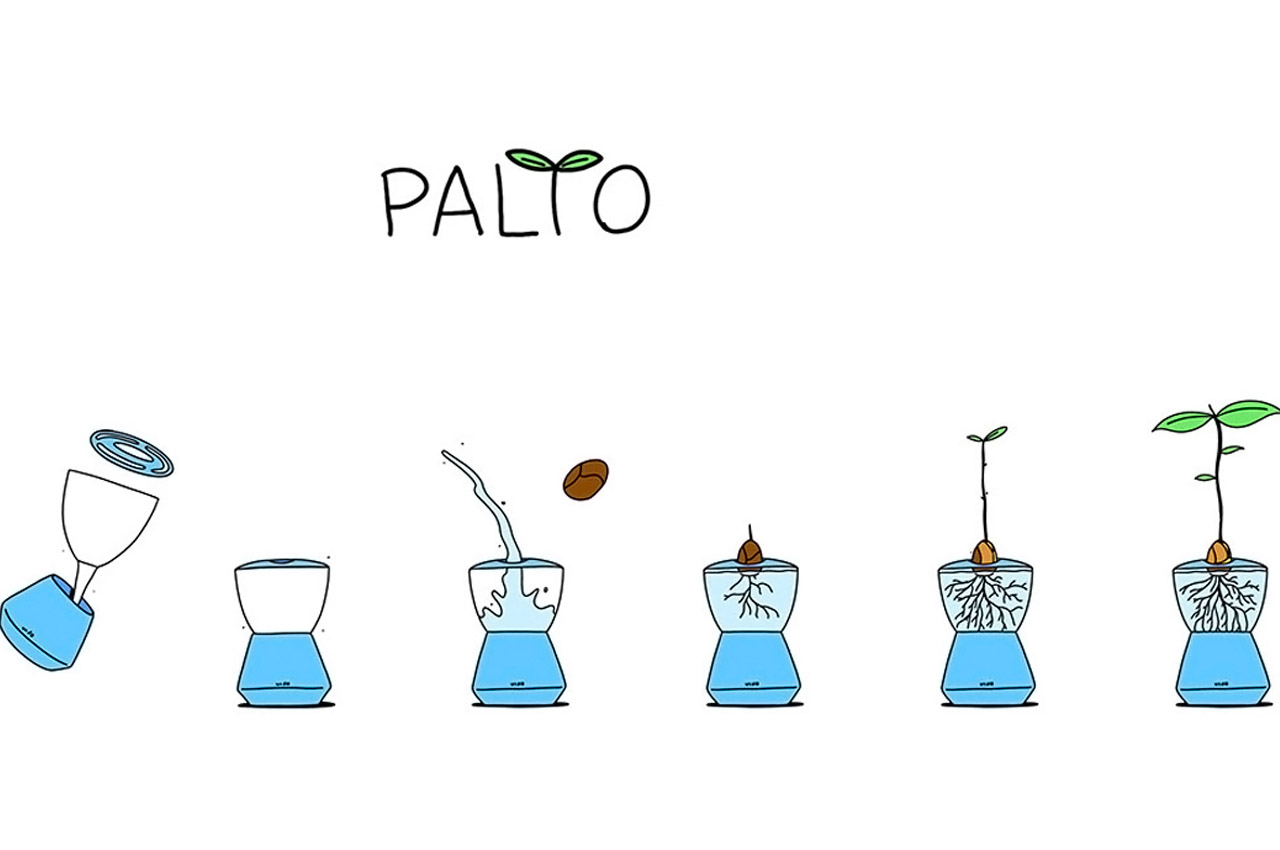

While more extensive hydroponic systems are being offered for homes, industrial designer Lautaro Lucero has germinated the idea of something simpler. He has conceptualized the Palto Hydroponic Pot that reuses old glass goblets to grow avocado. Lautaro accidentally broke the bottom half of his glass goblet, and his basic instinct was to make something out of it. The big volume and the beautiful color of the goblet intrigued him to awaken the designer inside him, and hence the Palto Hydroponic Pot was born. The beauty of this concept is its practicability – anyone at home can take the design cues from Lautaro’s blueprint and recycle their broken or old goblet into a hydroponic planter. The creation not only germinates avocado right in your living room but looks so aesthetically pleasing. The mesmerizing caustic effect of the light refracting, as you see the plant germinate.

This is the first time I’m seeing a LEGO bottle made from actual transparent pieces. The bottle assembles around the ship, making it much easier to build the ship first and then construct the bottle (as opposed to authentic ship-in-bottles that are painstakingly assembled within pre-existing glass bottles). The bottle sports its own stopper, with a wax seal, all made from LEGO bricks, and rests on a nifty decorative stand, with a faux compass underneath. All in all, the entire artifact measures 3 inches in height, and 13 inches in width, making it a perfect thing to place on a mantelpiece or bookshelf.

KneeBlades are shaped like kneecap-sized turtle shells with attached wheeled dollies, transforming the knee pads into ones that help move your reach along with each home project. KneeBlades streamline home renovation projects like replacing floor tiles by maintaining your contact with the floor while allowing you to slide along as the project progresses. The dollies on KneeBlades can also be removed to use as regular knee pads. Then, for a more fixed design, knee creepers are shaped more like traditional rectangular dollies with knee-specific dips that are lined with silicone for a soft landing. Knee creepers also come with small sinks where tools and hardware accessories can be stored while getting the job done, setting them apart from KneeBlades.