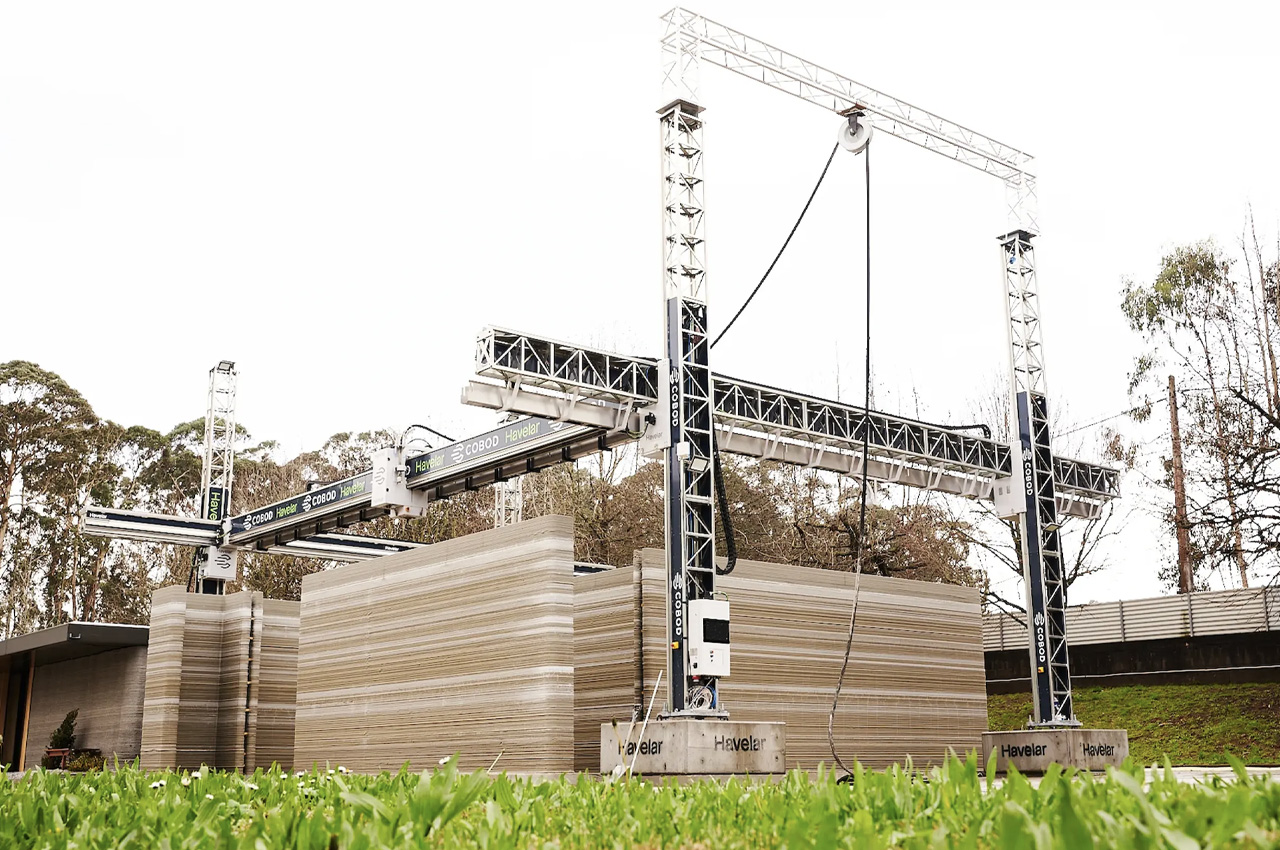

3D-printed architecture has been making waves ever since its inception. It is a fantastic solution to pricey housing, providing economical housing options to the population. Portagul-based Havelar is creating its very own inaugural 3D-printed home, which takes only 18 hours to print! The home is located in the Greater Porto area of Portugal’s second-largest city. It is designed to be an 80 sq ft two-bedroom residence which currently doesn’t have a name bestowed upon it. The home is printed using COBOD’s BOD2 printer.

Designer: Havelar

The home can be constructed for €1,500 per sq m, which is a great deal in comparison to the Porto average of €3,104 (almost US$3,330) per square meter. This economical price tag is because of the speed of construction provided by the 3D printer. The printer follows a blueprint and forms a cement-like mixture from a nozzle in layers. This forms the basic structure of the house. The printing process takes almost 18 hours, and then builders finish the construction by installing the door, paneling, windows, and roof. They also manually install any other amenities that are needed. Taking the human labour into consideration, the home was completed within two months.

The home by Havelar is a single-storey abode with telltale ribbed walls which implies that the home was built using a 3D printer. The interior includes a central kitchen and dining room, with two bedrooms, a living room, as well as a bathroom. The home is quite basic and minimal compared to high-end and luxurious 3D-printed homes you may have seen around, but taking the price tag into consideration it truly is a fair deal for what you’re getting.

“We want to team up with partners who see themselves in building sustainable and accessible communities,” said Rodrigo Vilas-Boas, Co-Founder of Havelar. “With €150,000 [$161,000], it’s possible for a young couple to have the home they’ve always dreamed of, in an area with good access and services.”

This home is the first 3D-printed home developed by Havelar, but the firm plans to amp up production and even reach carbon neutrality by 2030, by shifting to alternative construction materials like straw and earth.

The post 3D-Printed House Is Built in 18 Hours, Offering An Economical Housing Solution For The Future first appeared on Yanko Design.