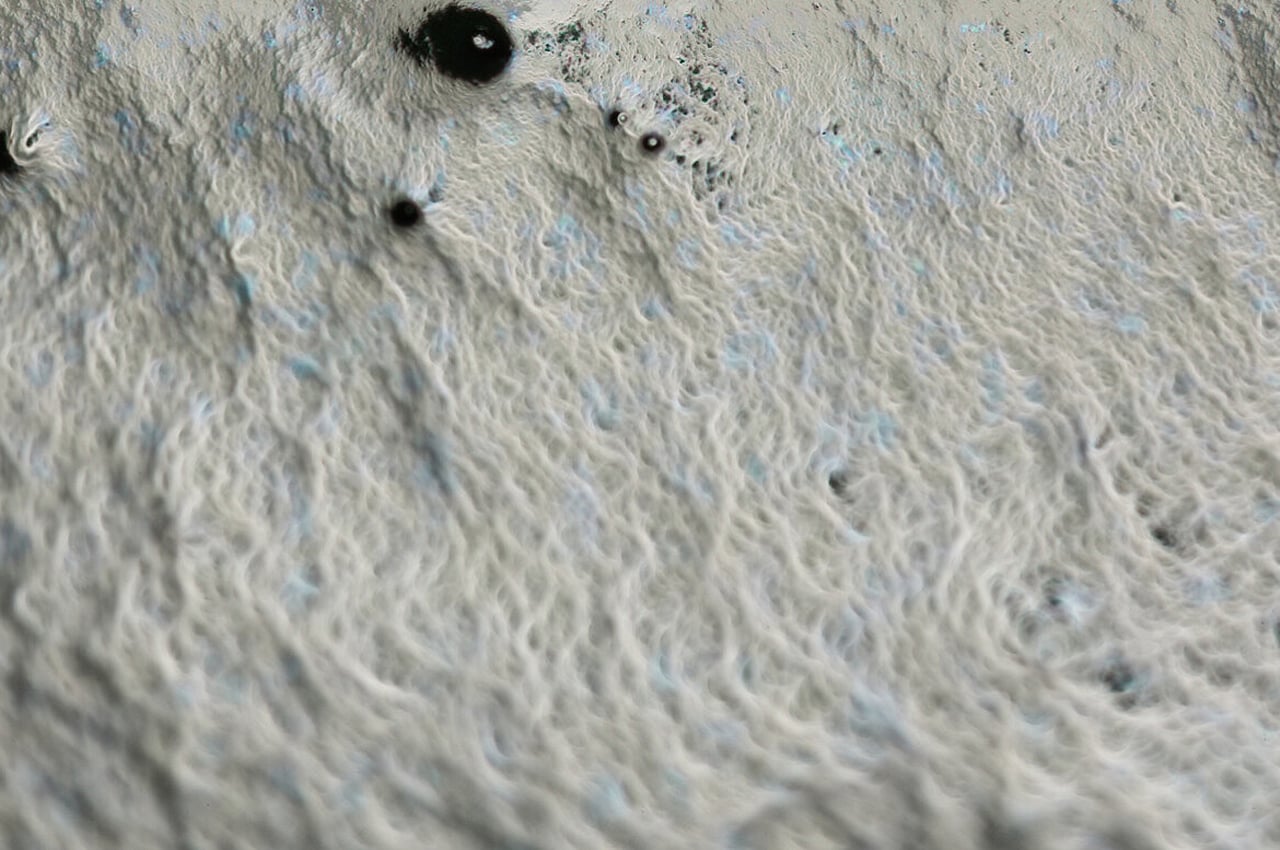

Vollebak grows black algae in giant ponds located in California, which is collected and heat-treated to concentrate it into a black powder to be used as a pigment for dye.

Every day, we wear clothes without knowing how they’re made. Unless you’re already buying clothes from sustainable brands, most of the clothing we wear is produced from material that isn’t harvested responsibly, let alone biodegradable. Take the color black–our favorite everyday black t-shirts are colored by a pigment derived from petroleum called carbon black. However, Vollebak, a clothing brand that uses technology to produce sustainable t-shirts and bottoms, aims to reinvent the way that the color black is made.

Carbon black is a color pigment that’s used to dye our clothing black. After large plots of land called tar sands are stripped of all pre-existing vegetation and animal life, carbon black is extracted from the petroleum stored underground. Noticing the unsustainable practices of producing black clothing, Vollebak discovered that you don’t have to dig up any earth to access black algae.

Known for growing in ponds, black algae only needs sunlight and carbon dioxide to flourish. Having abundant access to a natural black pigment, Vollebak used material technology to collect and use black algae to dye their t-shirts black. The result? The Black Algae T-Shirt feels and looks just like a conventionally dyed t-shirt.

Each t-shirt from Vollebak is made from eucalyptus trees that are harvested from sustainably managed forests. Once the pulp from eucalyptus trees gets spun into a wearable fabric, each t-shirt is dyed with black algae ink, which continues to lock in the carbon dioxide it absorbed while still alive. In order to lock the carbon dioxide into the shirt for up to 100 years, Vollebak uses carbon capture technology to trap carbon dioxide at its emission source.

After harvesting black algae from their ponds, Vollebak puts the algae through a heat treatment that concentrates it into powder form. “The black algae ink has been engineered to be UV resistant so it will hold its color for years. But since this is a bio-based ink it won’t behave exactly like a petroleum-based ink. Over time the black color may brighten around the edges next to the seams. To make the algae last for as long as possible we recommend hand washing the t-shirt in cold water with as little detergent as possible.”

The T-shirts themselves are produced from eucalyptus trees that are harvested from sustainably managed forests. “The rest of the t-shirt is made from wood pulp from sustainably managed forests. Eucalyptus, beech, spruce are chipped and pulped, before being turned into fiber, then yarn, and finally fabric. All the wood is harvested from sustainable forestry plantations and certified by both the Forestry Sustainability Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC). Representing over 700 million acres of certified forests, the PEFC is the largest forest certification system in the world.” Instead of dyeing the shirt’s individual fibers black, Vollebak dyes the entire outer surface of their shirts in black algae ink, which is why the final color of each t-shirt is more of a very dark grey marl.

Since all the materials used to produce their Black Algae T-shirt, the shirt can biodegrade in about 12 weeks. Once the material has disappeared just the black algae ink will remain in an almost imperceptible, safe and non-toxic state. And while other organic materials release carbon dioxide when they decompose, this ink will continue storing its carbon for over 100 years.

Designer: Vollebak

Engineered to be UV-resistant, the t-shirt will hold its color for years.

“The wood is turned into [the] fabric using an environmentally responsible and closed-loop production process. In practice, this means that over 99% of the water and solvent used to turn pulp into fiber is recycled and reused.”

Since its not petroleum-based ink, the black algae ink dye will brighten near the t-shirt’s seams and edges.