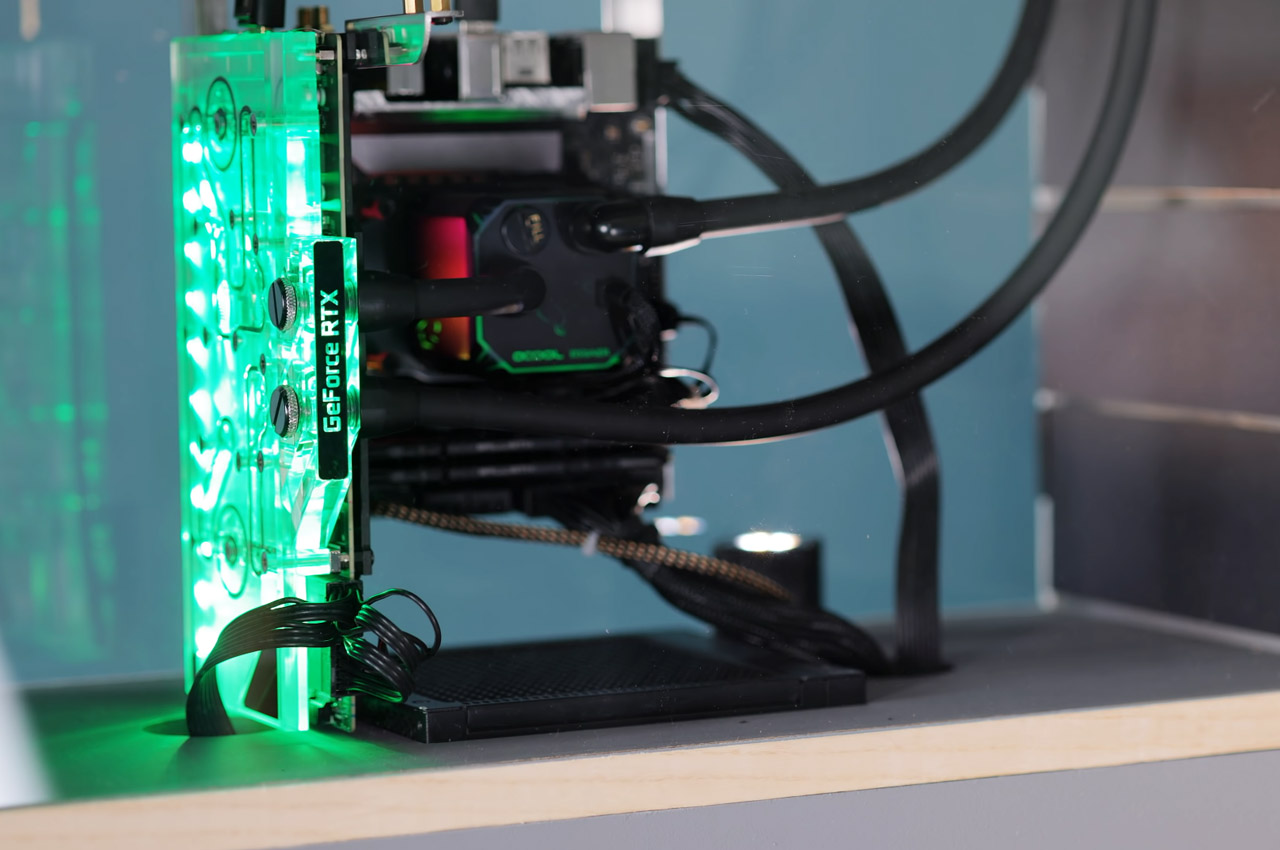

Ken Pillonel, the engineer and YouTuber behind the world’s first USB-C iPhone and AirPods, just revealed upgrades for the AirPods Pro. His custom build features a new 3D printed case that can be opened and repaired (thanks to screws on the back), along with a USB-C connector on the base instead of the conventional Lightning port. Pillonel’s build isn’t just a one-off custom project, though. He’s made his project open-source and available to the public, allowing pretty much anyone to upgrade their own AirPods Pro.

“The first and second generations of AirPods made by Apple were given a score of 0 out of 10 by repair specialists at iFixit. A few years later, the Pro version came out, and it still received a 0 out of 10”, Pillonel told Yanko Design. After creating the world’s first USB-C AirPods, Pillonel received a lot of requests for giving the AirPods Pro the same treatment. “The goal was to find a solution that gives a second life to the allegedly unopenable cases, which all face an inevitable end of life because of their built-in battery,” he said.

Designer: Ken Pillonel

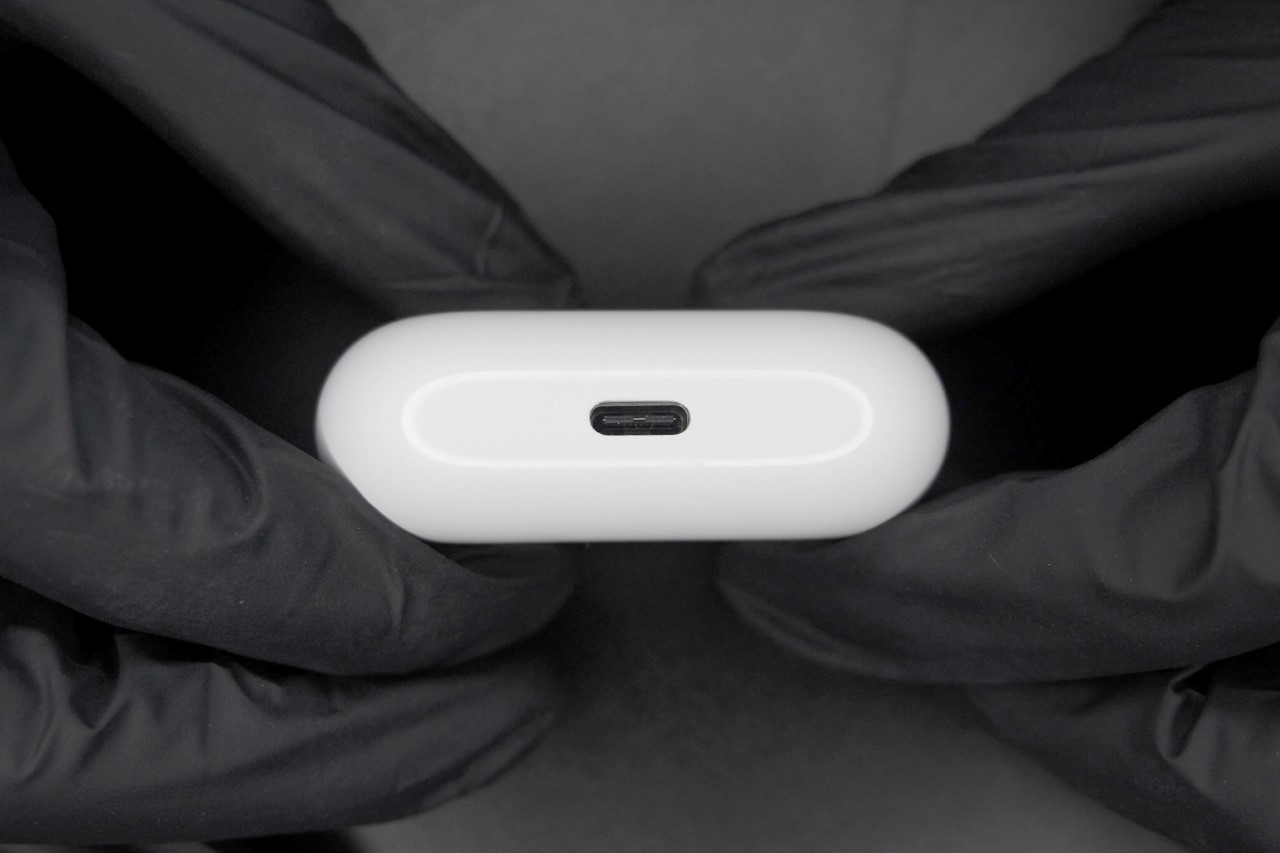

Not only is Pillonel’s AirPods Pro case more sustainable and repairable now, it’s also USB-C compatible (a feature that will come in handy as Apple plans to launch a USB-C iPhone soon)

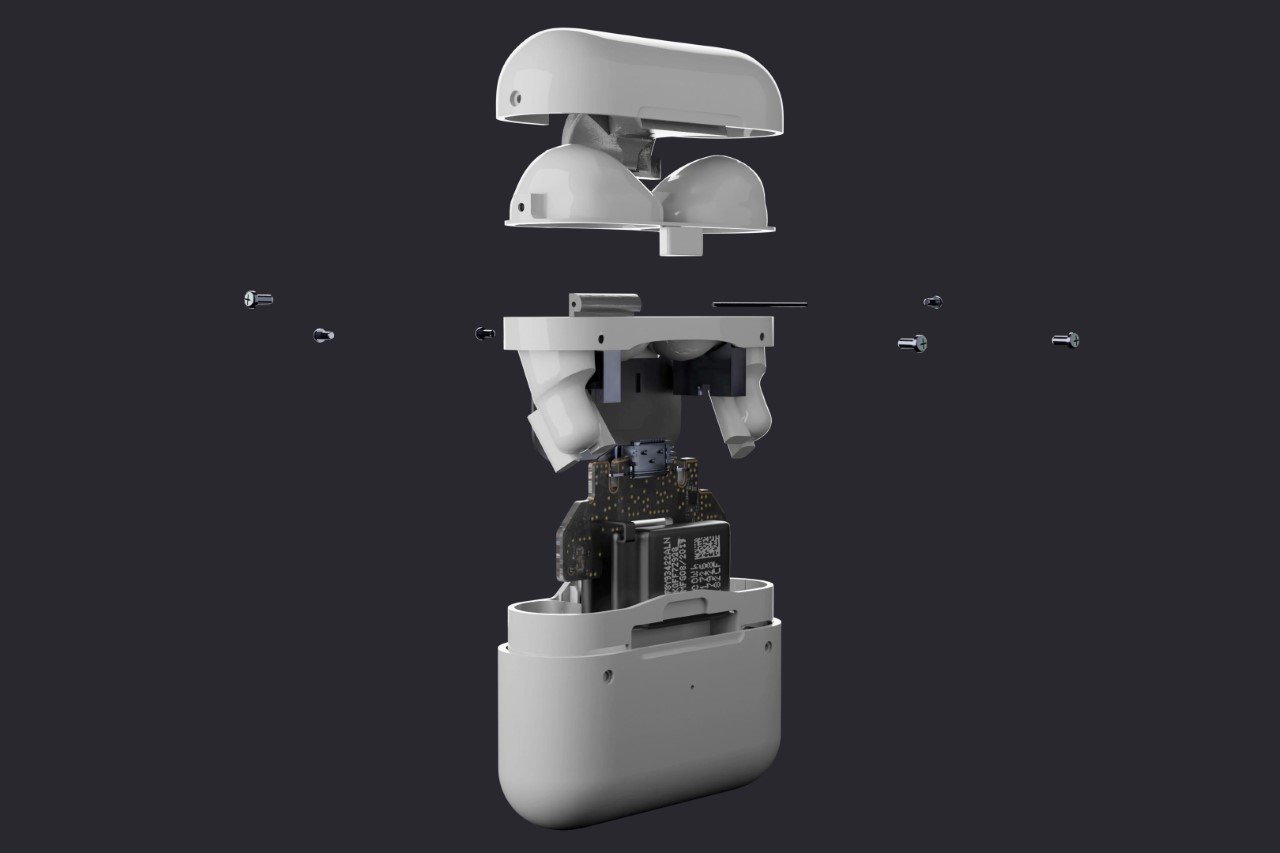

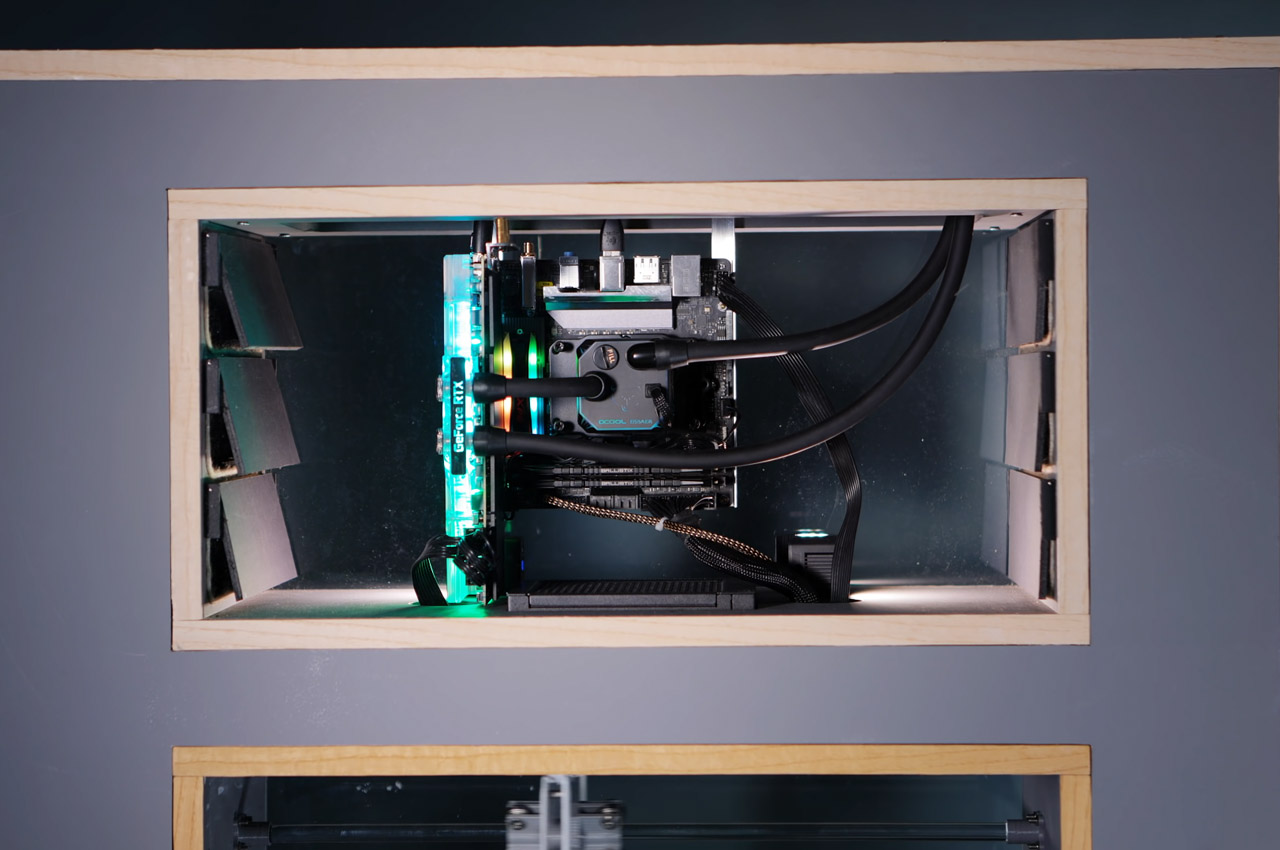

Every AirPods case is hermetically sealed, and even an Apple employee will tell you that it’s cheaper to just replace the thing than it is to repair it. Pillonel’s journey started with needing to overcome this hurdle, and the easiest answer was to just build a new case instead of somehow trying to salvage the existing one. Pillonel was lucky enough to get 2 cases from people willing to donate them, which he used to create his own mockup. The cases were first inspected to see the internal components, and then their forms were scanned, modeled, and 3D printed with screw holes and an easy-to-open build.

The new case is practically identical to the original, except for the presence of 6 screws that hold the case and its lid together in place.

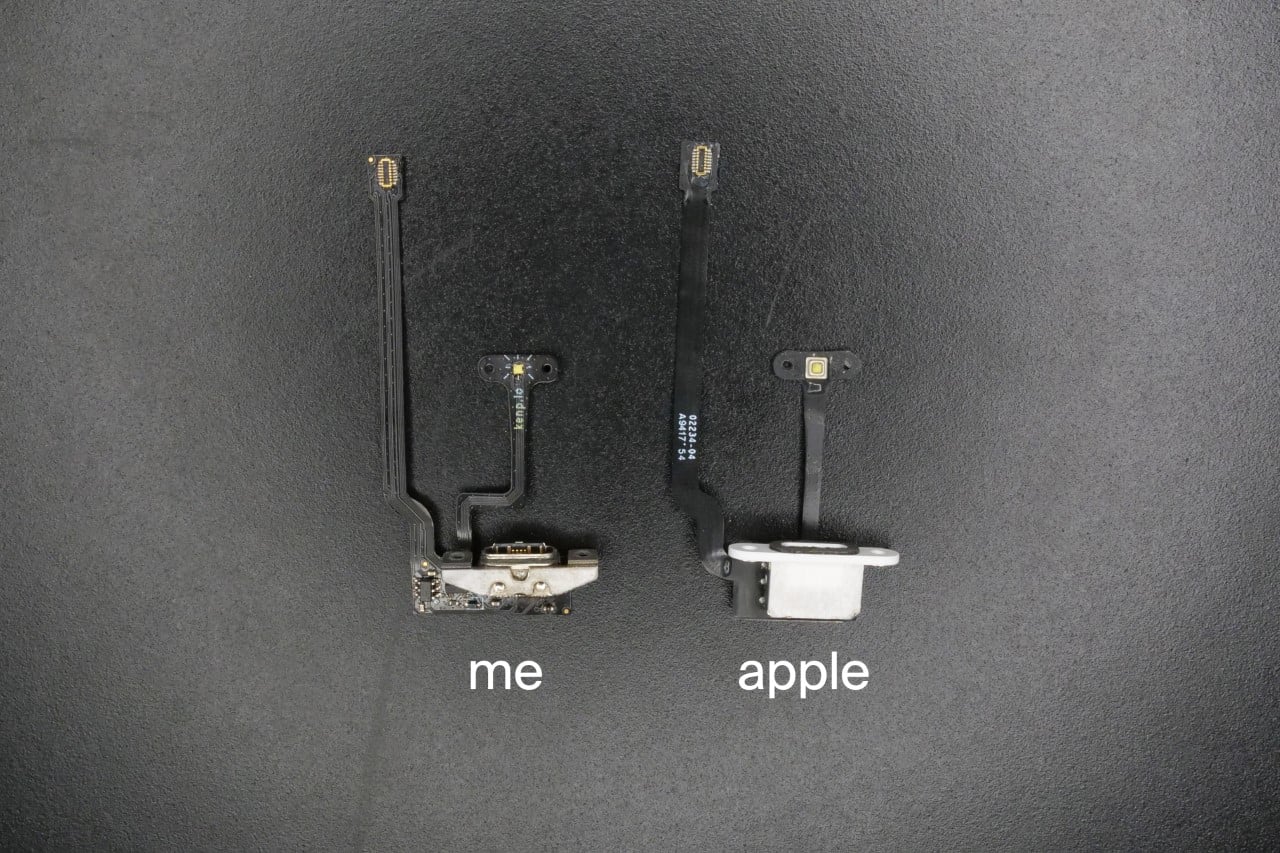

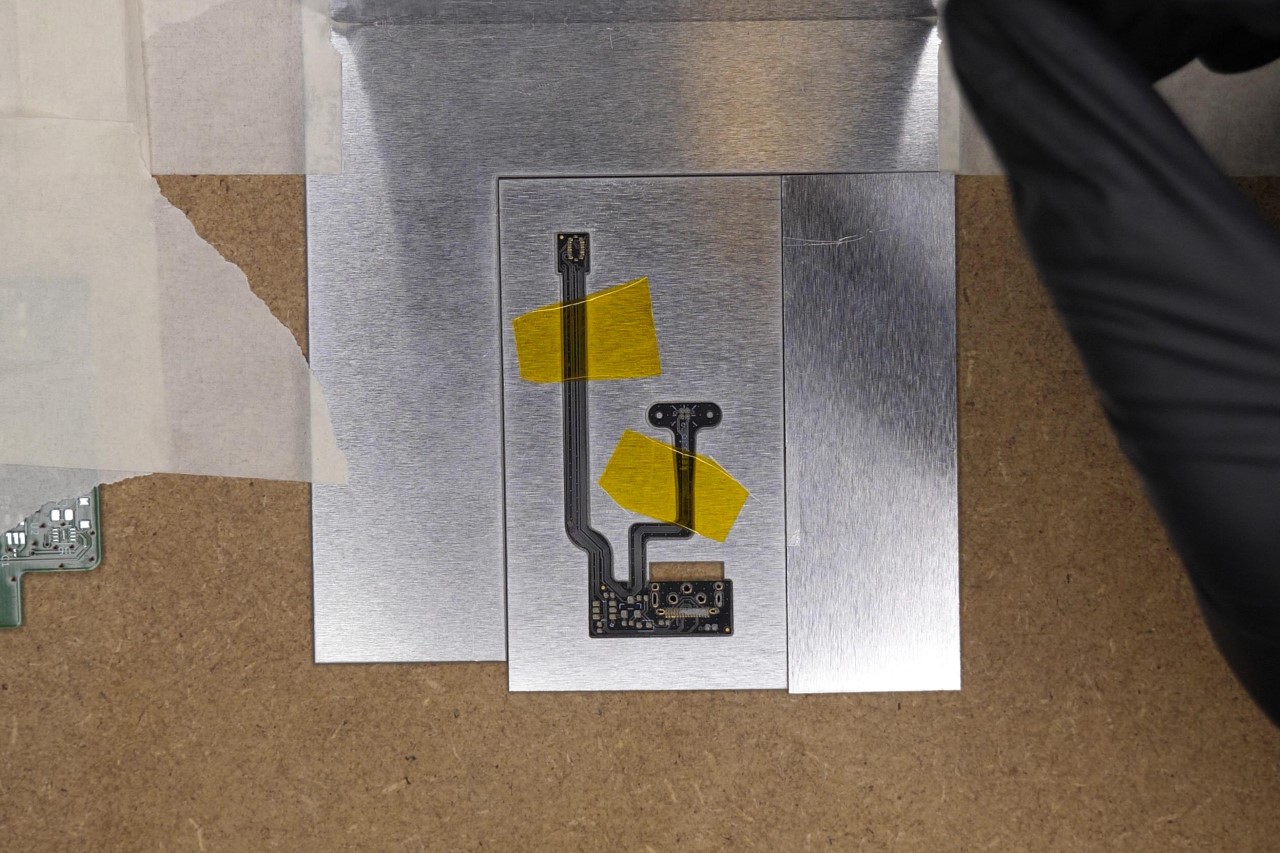

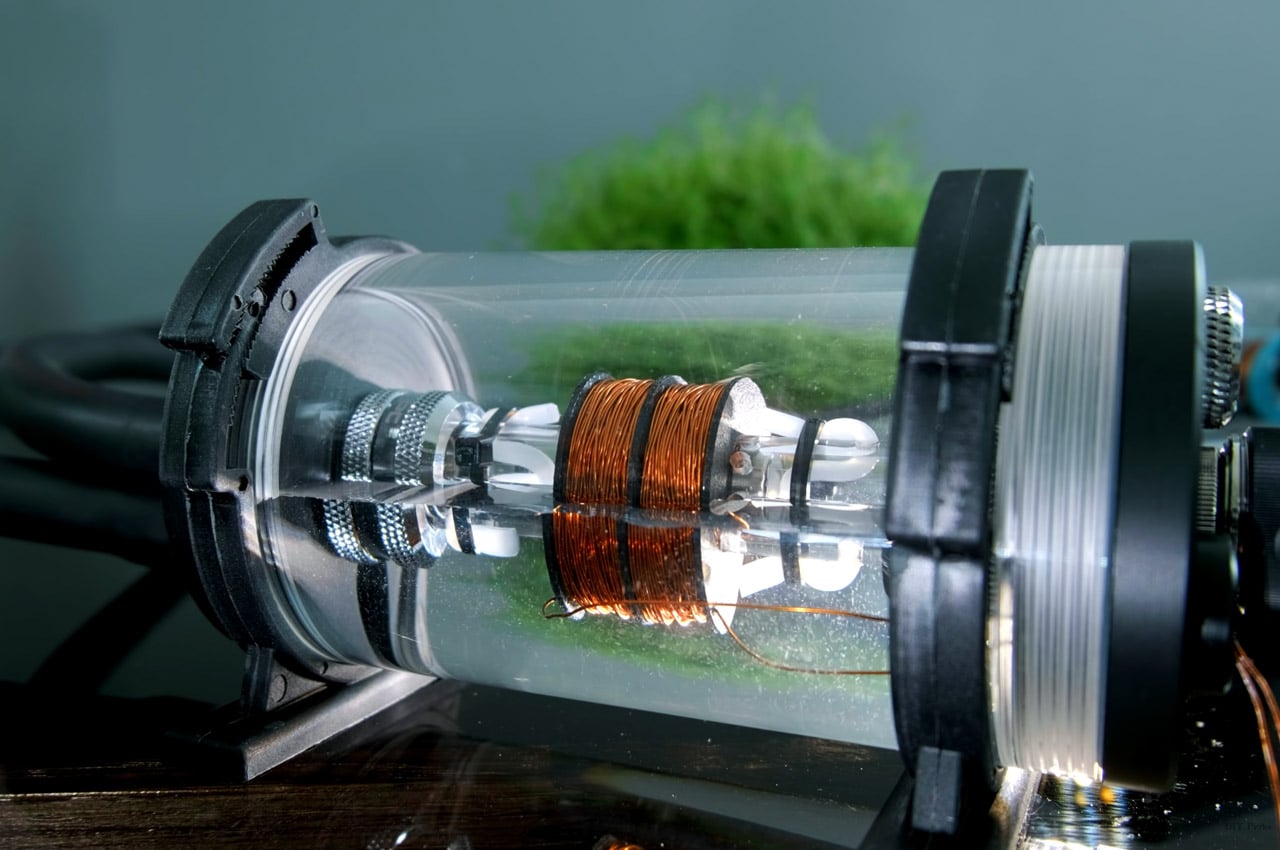

The tougher challenge, however, was upgrading the AirPods Pro to USB-C. “A replacement battery can be purchased online, but it is the only replacement part available. If a charging port is broken, there is no way to replace it except by getting a replacement part from another device”, he said. Given Ken’s prior experience in the matter, this seemed easier the second time around. He scanned the Lightning module and made his own custom PCB, to which he attached a USB-C port. He even created the custom plastic bracket that helps the component mount onto the case, pretty much completing the hardware-intensive part.

An issue that Pillonel unexpectedly faced was with the LED connected to the charging module. Apple’s AirPods come outfitted with a charging LED that glows red, green, or white (RGW), but most LEDs Pillonel could find were RGB, offering red, green, and blue instead of white. It took him a while to finally find a vendor in Japan who had RGW LEDs that fit his size requirements. With this, his charging module was complete and ready to be put into the new and improved AirPods Pro case.

“I realized that 2 million people watched the last video where a similar project is done for the original AirPods, and only a few attempted to repair it as shown,” Pillonel mentioned. He was banking on Chinese manufacturers copying his PCB template and selling their own parts on AliExpress for people to buy, but that didn’t seem to pan out. With this project, Pillonel’s taking matters into his own hands by actually selling the charging module on his website for people to buy. You can even find schematics for 3D printing your own AirPods case, on the off-chance that you happen to break yours while prying it open. In all fairness, the new case makes much more sense, given that it’s easy to open if you ever need to replace the battery on the inside (which will eventually degrade after a year or two).

A Master’s in Robotics from the Swiss Federal Institute of Technology, Pillonel has more projects in the pipeline that include a transparent AirPods case as well as upgrades for the TWS earbuds themselves.

The post World’s first USB-C AirPods Pro comes with a sustainable, repairable case. Here’s how to make your own first appeared on Yanko Design.

After months of leadup, Apple's video streaming service, TV+, is ready to launch. With this being Apple's first foray into original video content, we've detailed the ways you can get access to the platform without paying the full $5 per month right a...

After months of leadup, Apple's video streaming service, TV+, is ready to launch. With this being Apple's first foray into original video content, we've detailed the ways you can get access to the platform without paying the full $5 per month right a...