The plastics used to build car tires are the same plastics used to make chewing gum. From the moment we spit our gum onto the ground, it will take upwards of 50 years for that one piece to even begin decomposition. Noticing the wasted potential of chewing gum and the harmful effects it poses on the environment, design students Hugo Maupetit and Vivian Fischer decided to collect wads of discarded chewing gum out of which they molded and constructed wheels for skateboards.

After noticing that discarded chewing gum, made from synthetic rubbers, could be repurposed to construct wheels for skateboards, Maupetit and Fischer visualized a future partnership with Mentos and Vans. In the imagined collaboration, they worked together to take the gum from the streets and bring the gum back to the streets in a sustainable way. “Our initiative is supposed to clean the streets in a sustainable way. That is why we invented a system that will transform used wheels and turn them into new ones,” Maupetit and Fischer explained. “No more waste is created and the material stays in use.”

Initiating the collaboration, Maupetit and Fischer suggested that ‘gum boards’ be installed throughout their university city of Nantes, where residents could tack their finished chewing gum. As the gum boards filled up, the individual pieces would be collected, cleaned, molded together with a stabilizing agent, and stained with natural dye to form the wheels’ bases. The vibrant color of chewing gum along with its rubbery texture makes it a playful, yet tough choice for tire production.

People have been chewing on gum since the 1860s, but it was only after World War II that manufacturers began using synthetic rubbers, like polyethylene and polyvinyl acetate to make chewing gum. Plastics, like synthetic rubber, are able to be molded, pressed, and hardened into different shapes, making the building material relatively durable and easy to work with. Plus, there’s no shortage of supply– it’s everywhere.

Designers: Hugo Maupetit and Vivian Fischer

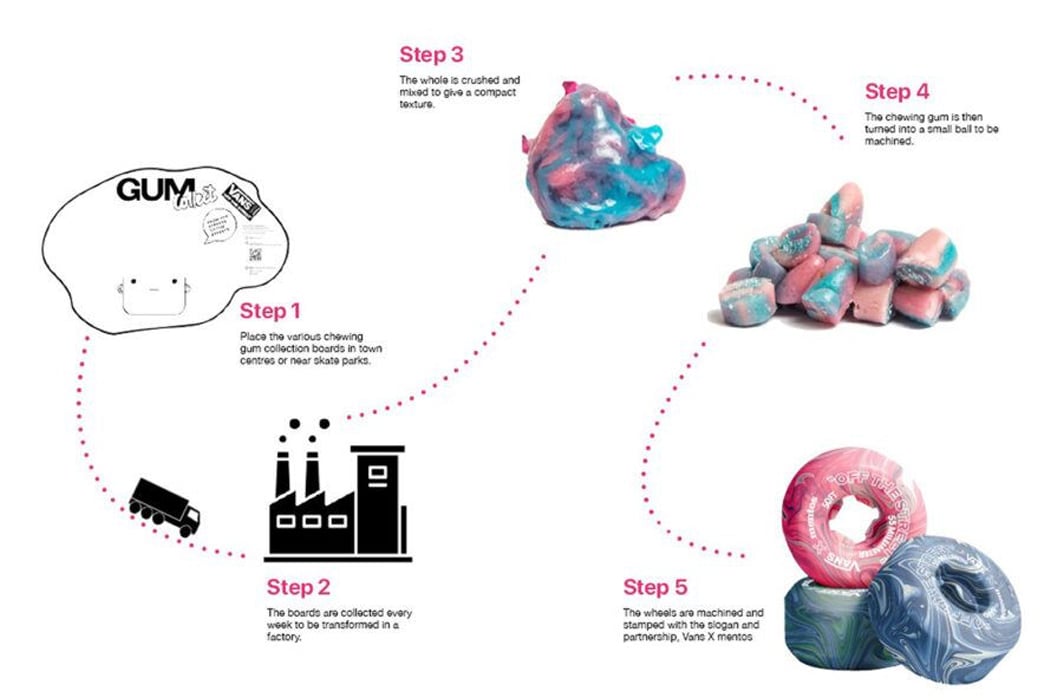

In an imagined collaboration with Vans and Mentos, Maupetit and Fischer conceived a mode of operations for their “Off The Street” gum-wheel initiative, including gum collection and tire production.

Gum boards throughout the city designate a spot for passersby to tack their gum for future collection.

Once the gum boards are filled up, they’ll be collected for future cleaning, molding, and staining.

Finally, following the mold and stain manufacturing process, wheels can be made available in stores for skateboarders to purchase.