We all know how bad plastic is for the planet, but no one will deny its versatility and affordability. Until we’re able to create a truly sustainable replacement that’s just as cheap to make, all we can do is take measures to reduce their impact on the environment. That might mean using bio-plastics, or it may mean reusing and recycling plastic into some other form.

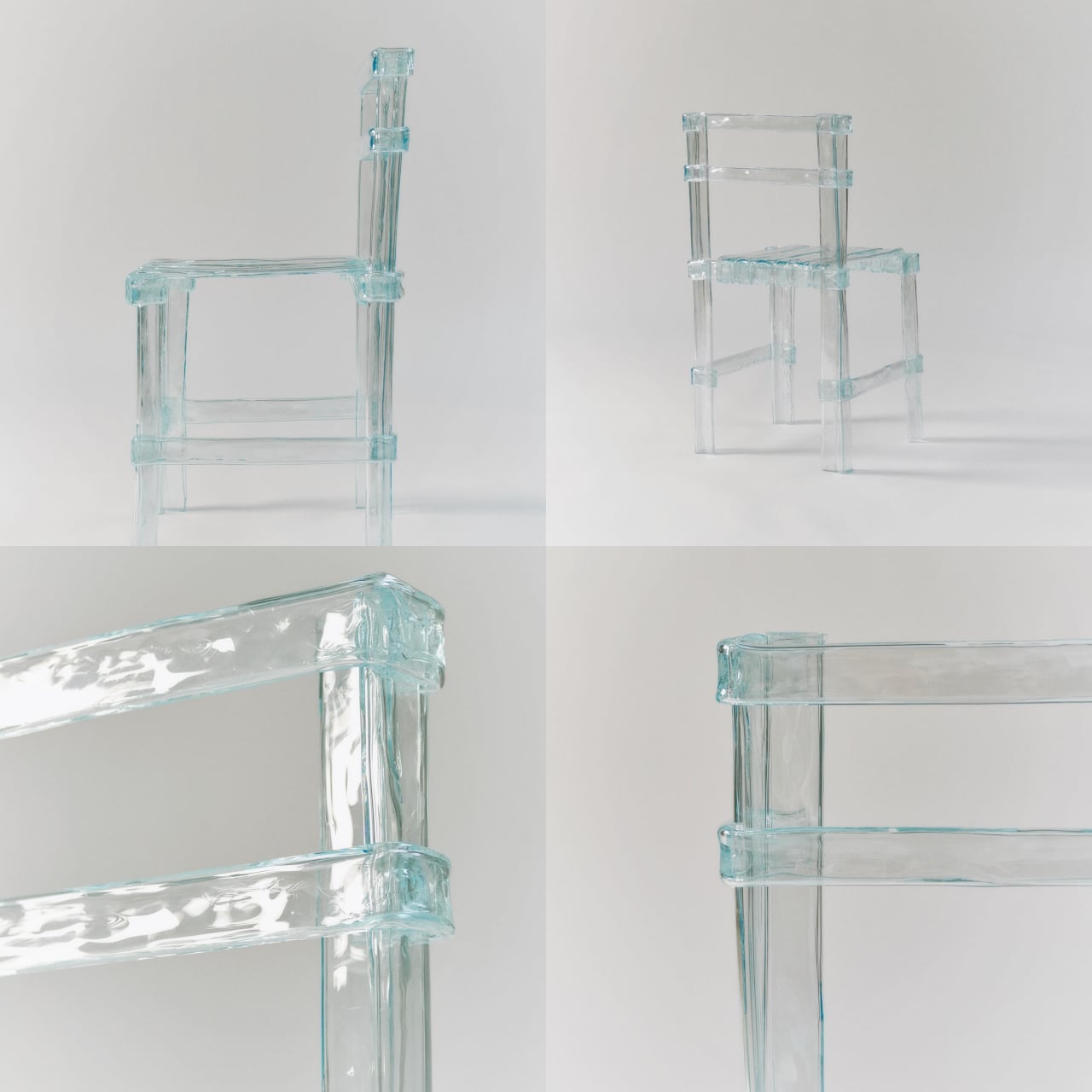

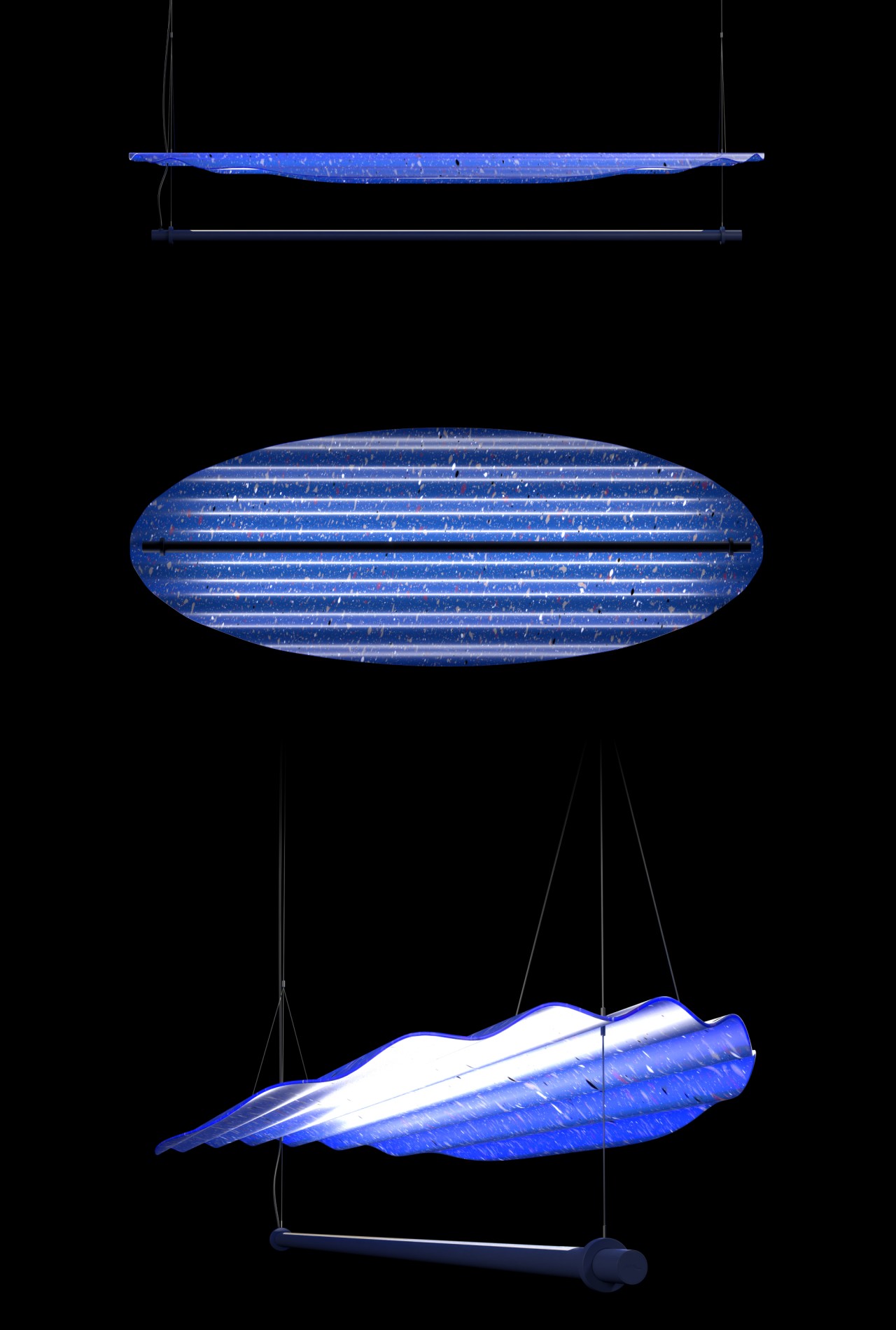

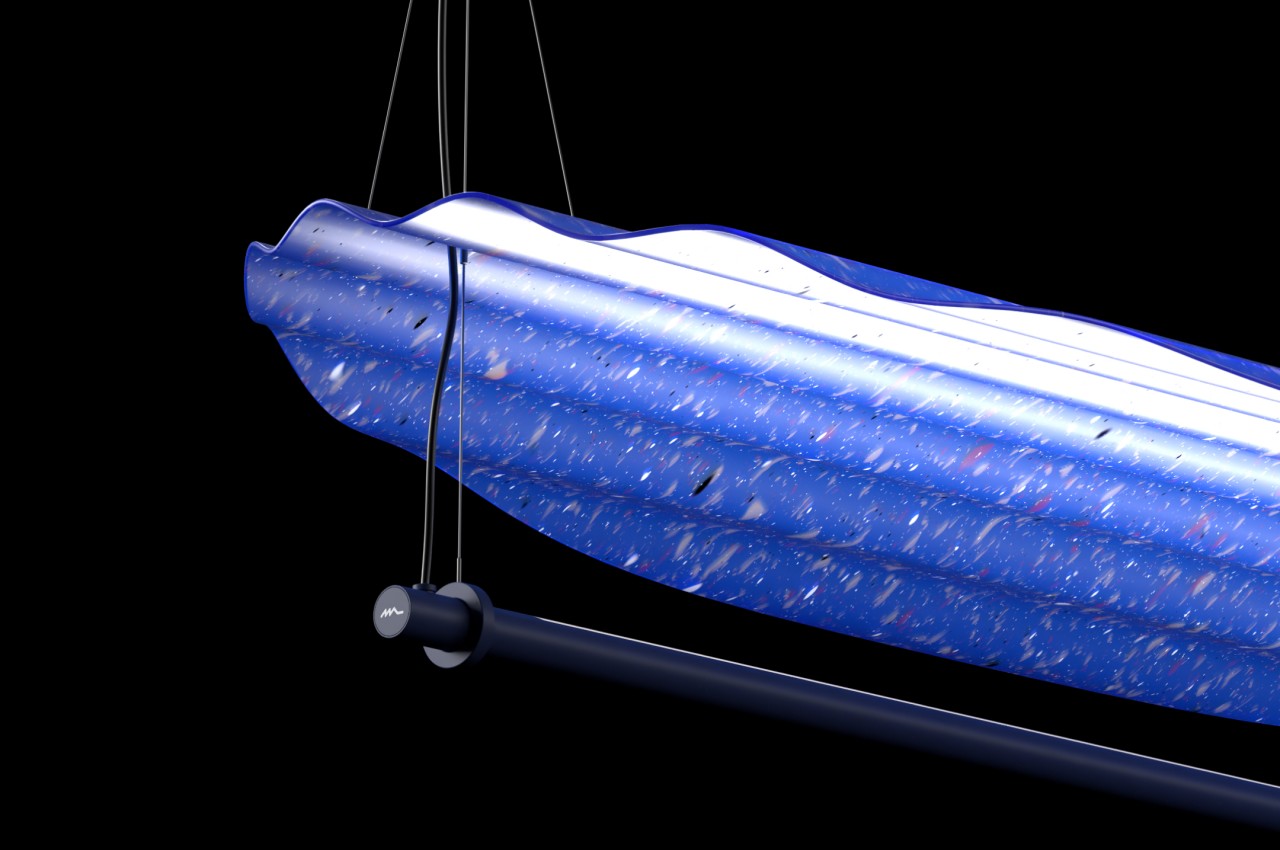

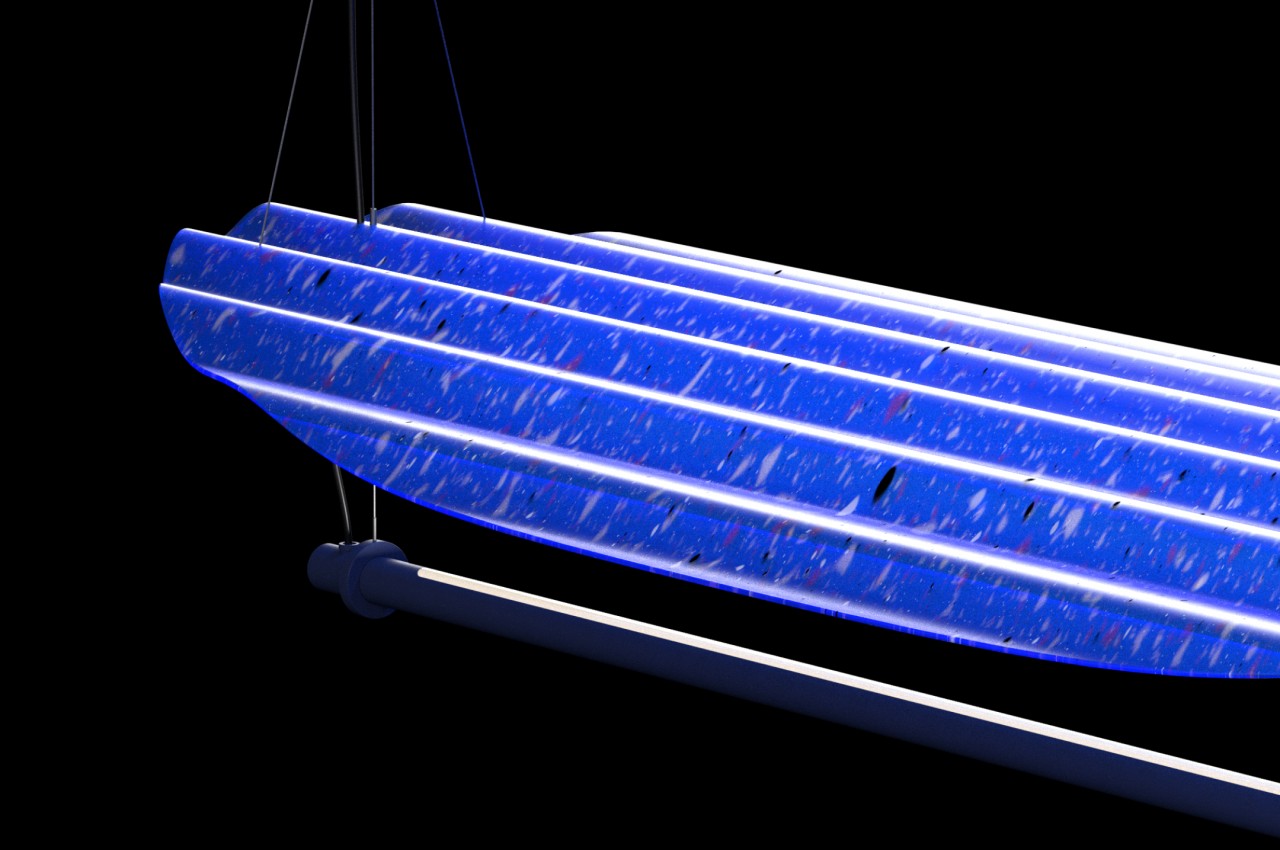

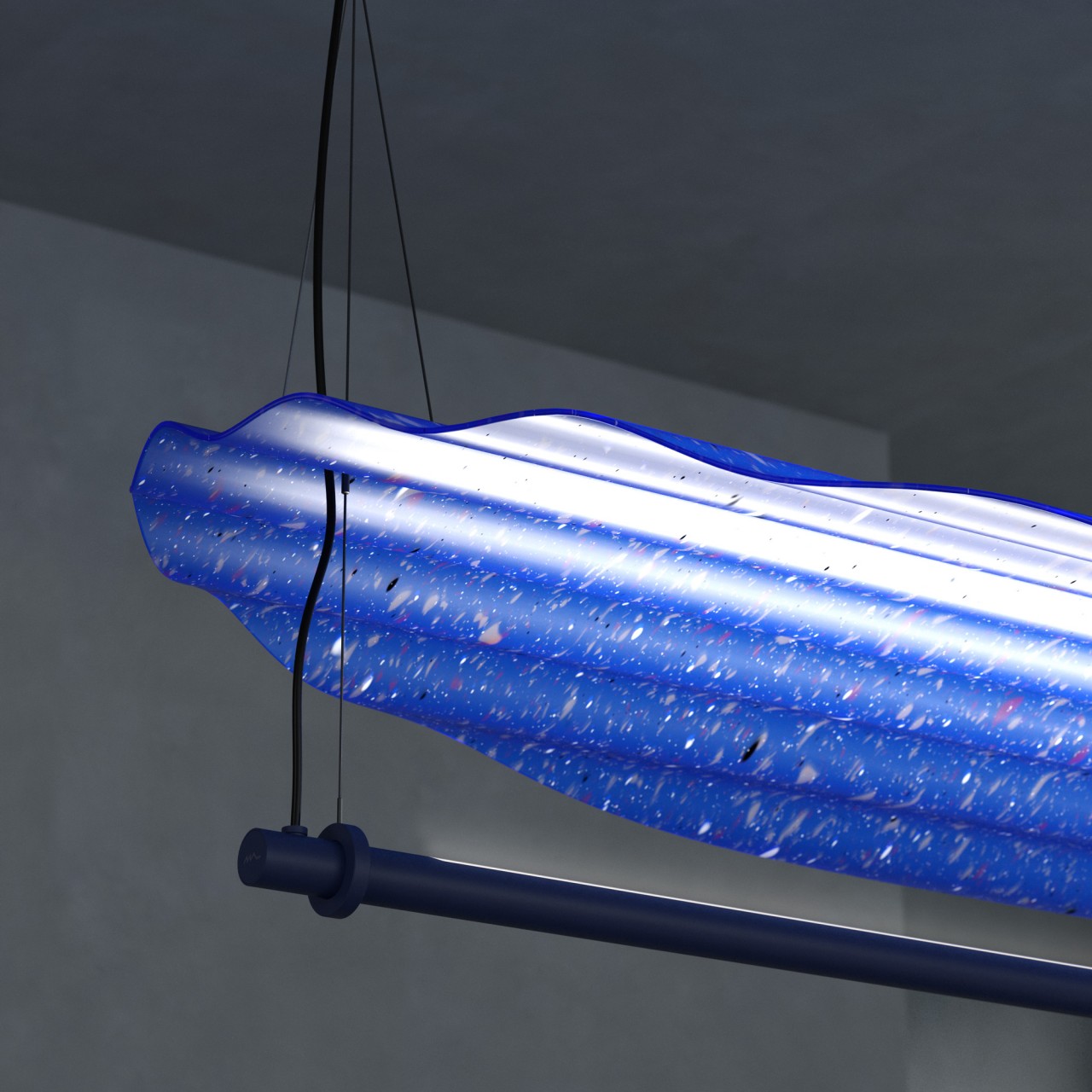

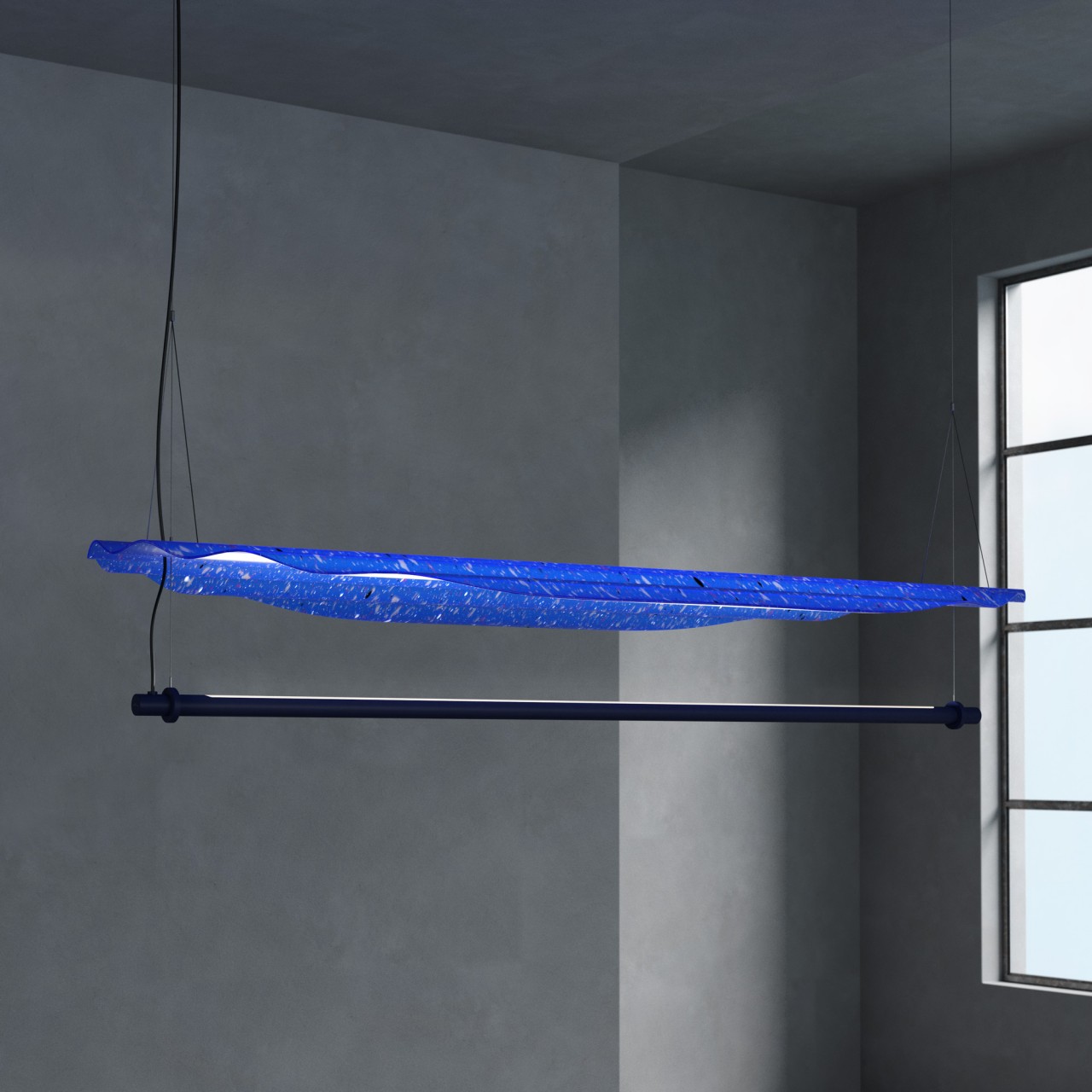

Transforming plastic into new materials isn’t exactly new, but this innovation puts a new spin on that idea. Not only does it recycle plastic without using binders or glue, it also makes the resulting material almost as strong and as beautiful as stone. The result: striking furniture made almost 100% from plastic.

Desingers: Jared Seifert, Lauren Copping (Design Declassified)

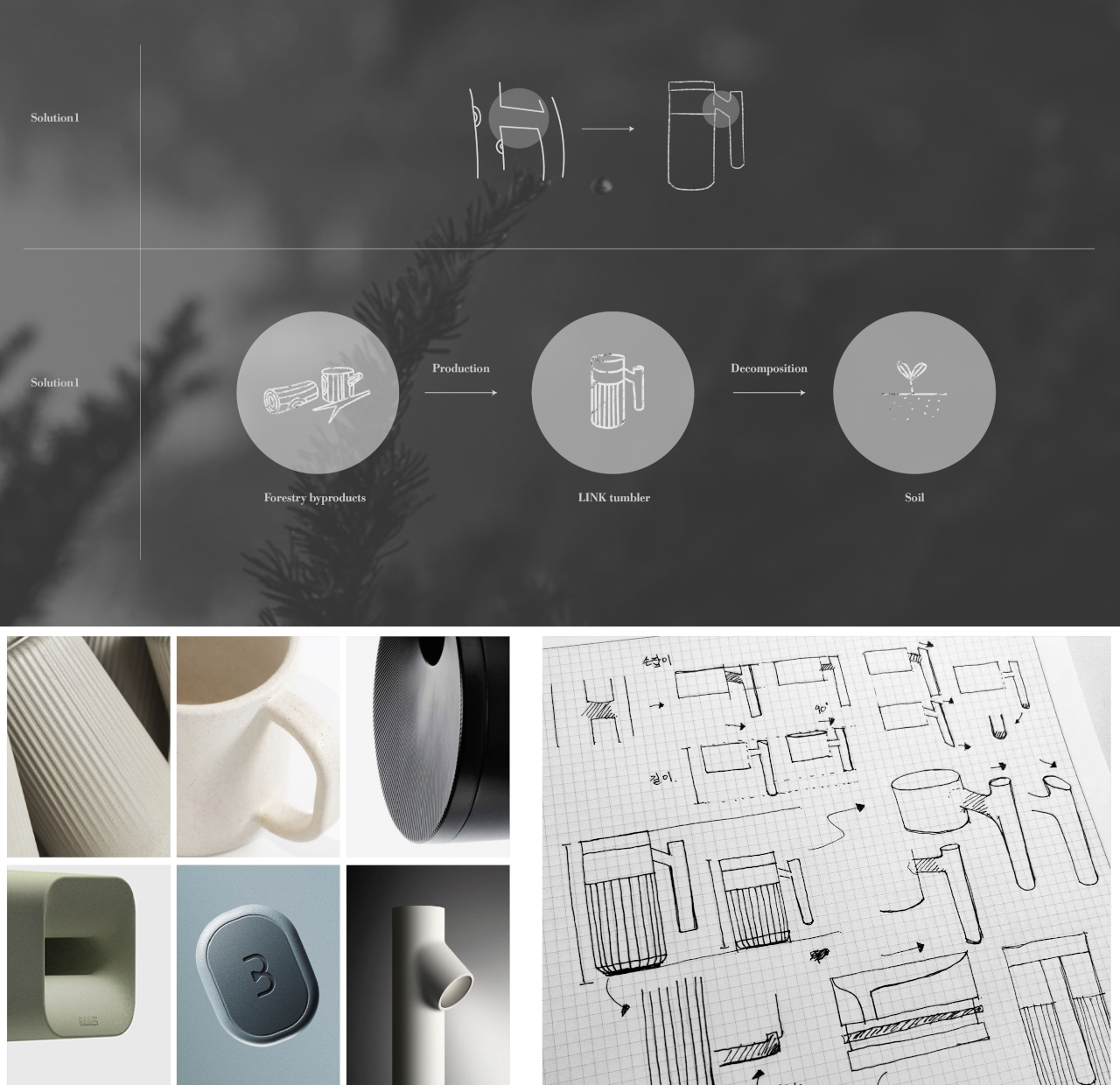

There are plenty of ways to recycle plastic, but unlike wood or paper, the process involves a lot of water and energy. They also usually involve mixing some sort of binder or glue to keep the new material together, which ironically can make the new recycled plastic product less sustainable. And there’s also that distinct “recycled” aesthetic that may sometimes be seen as an advantage but can also be considered a flaw.

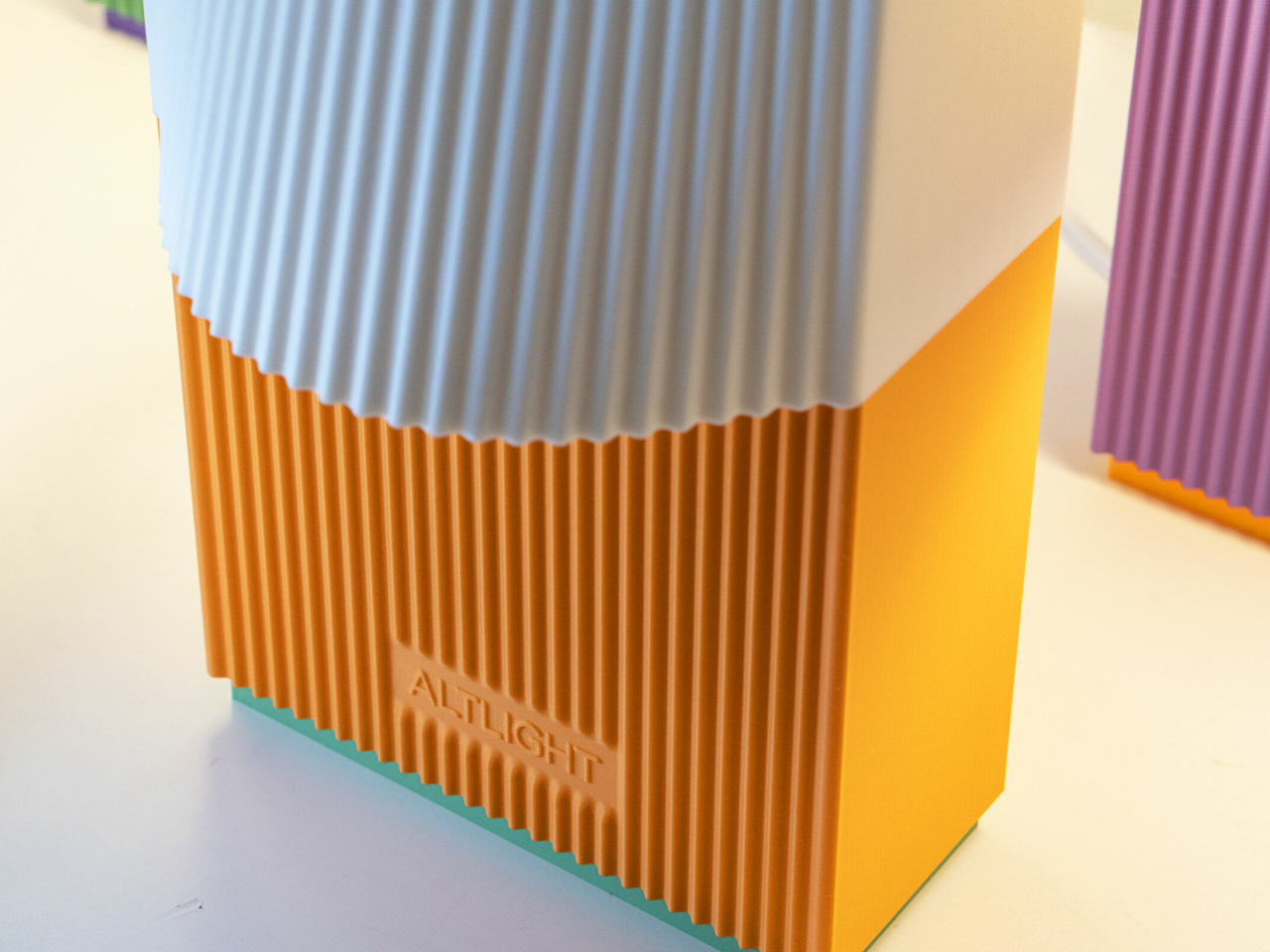

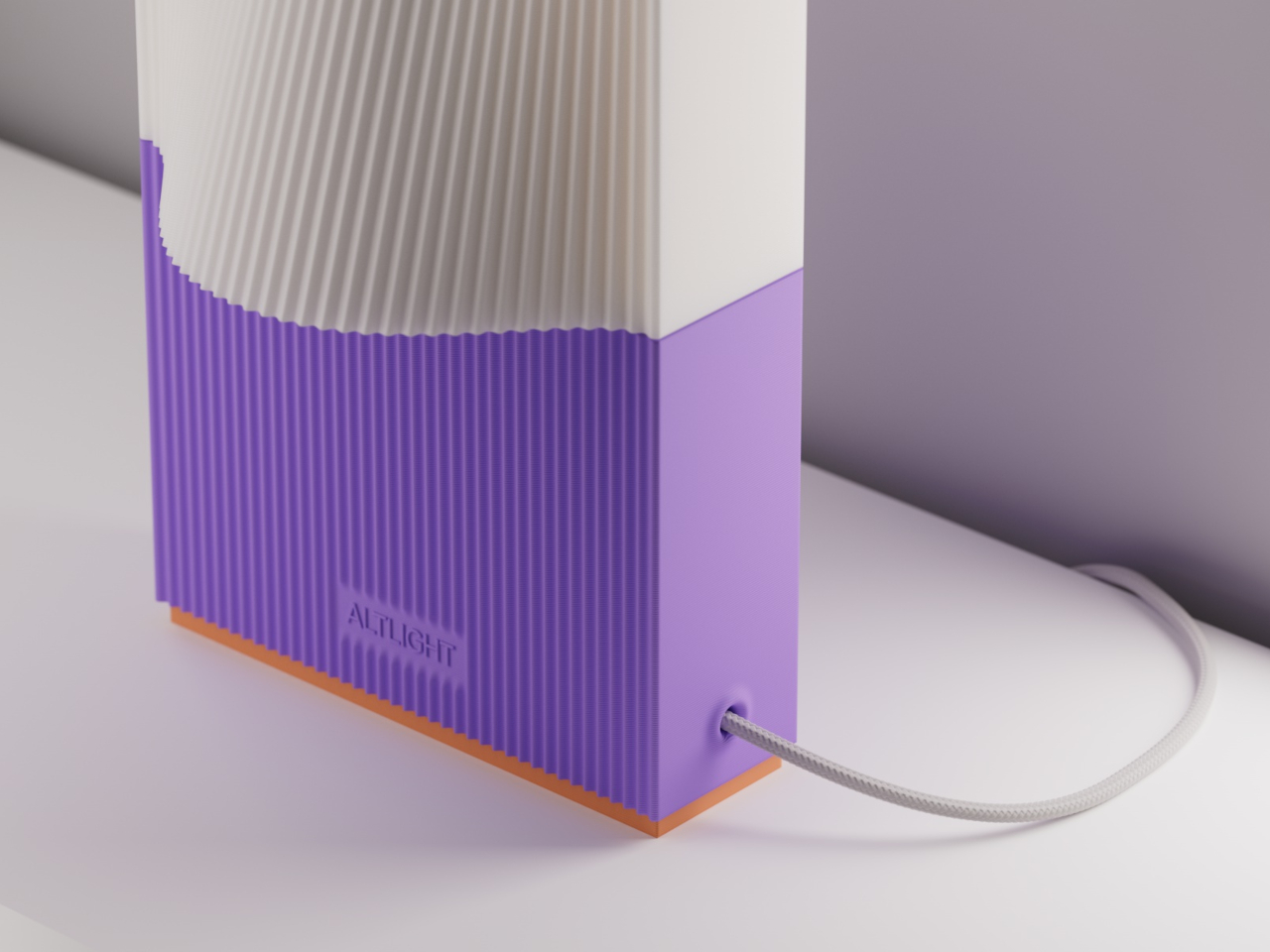

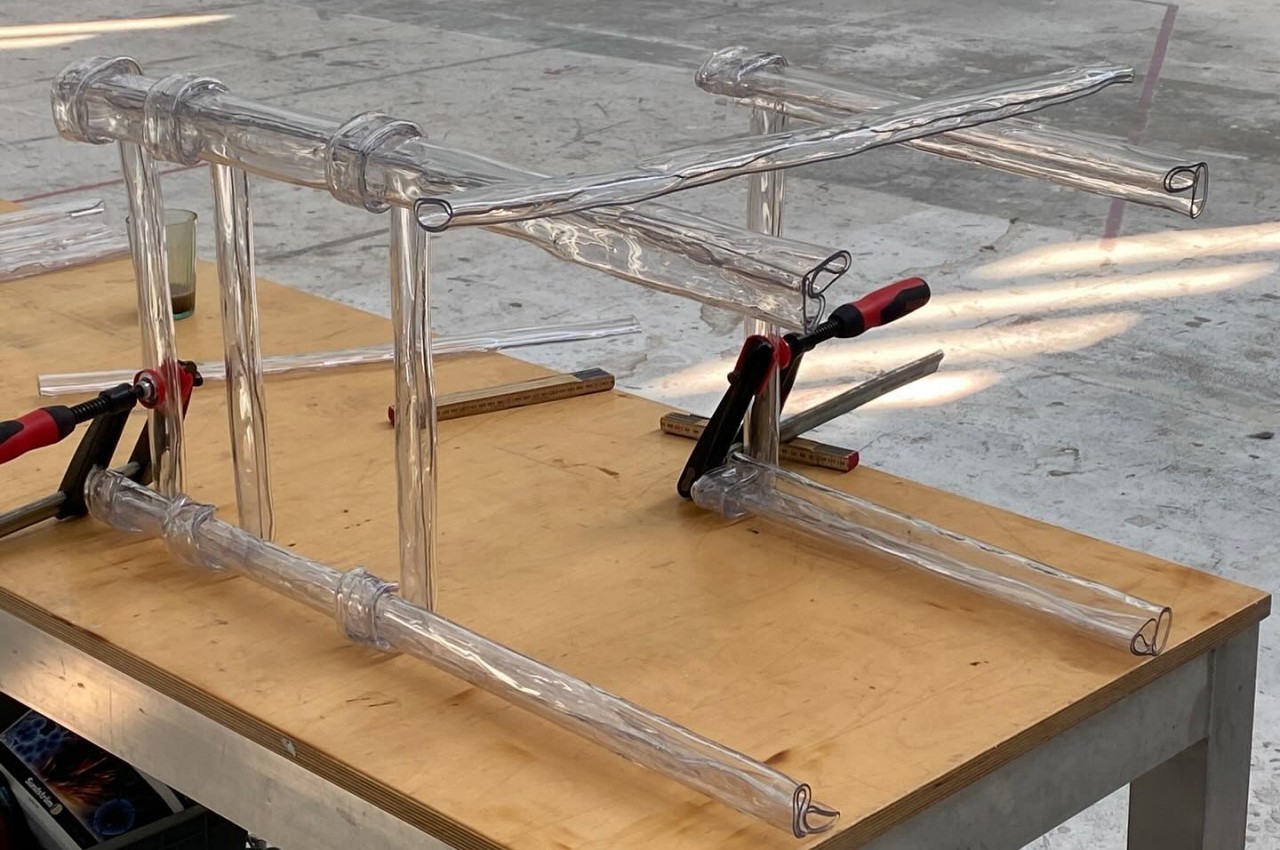

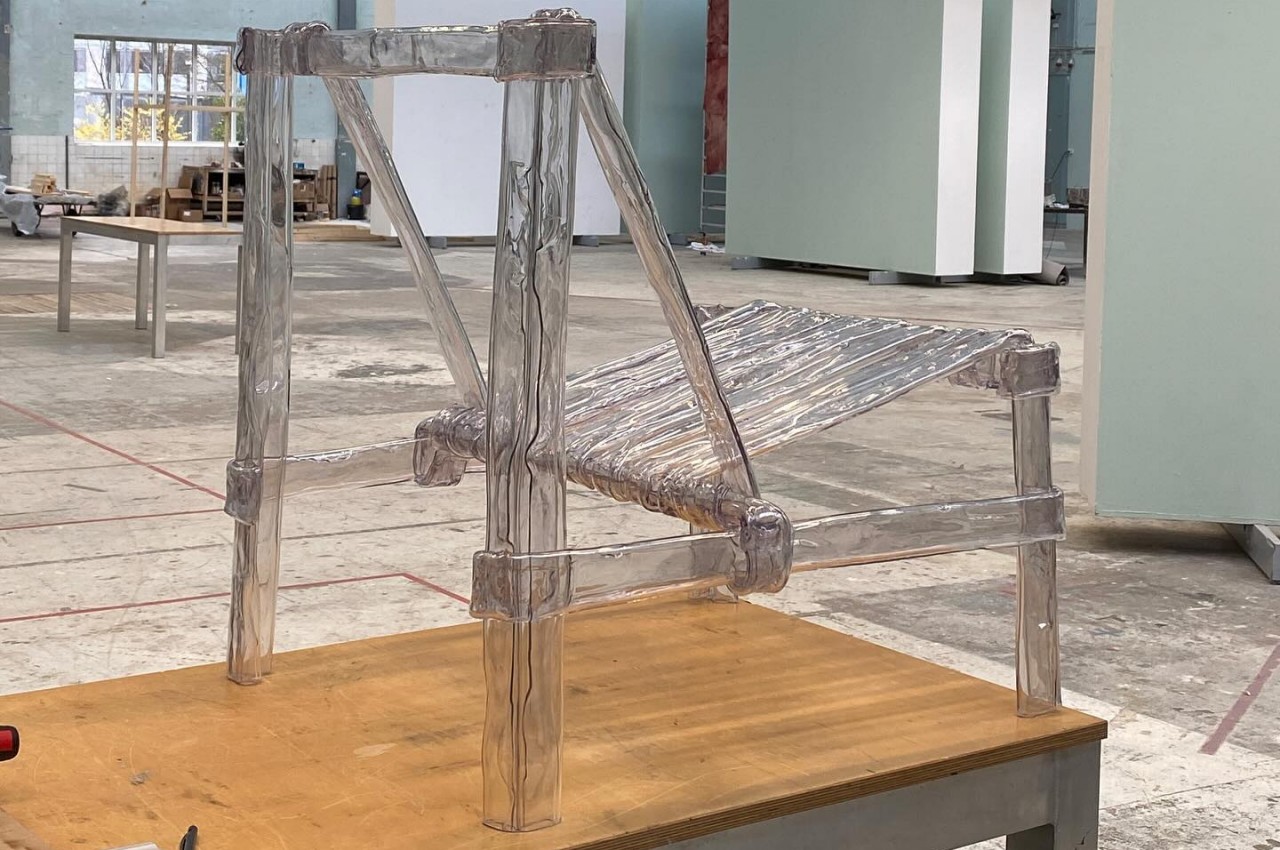

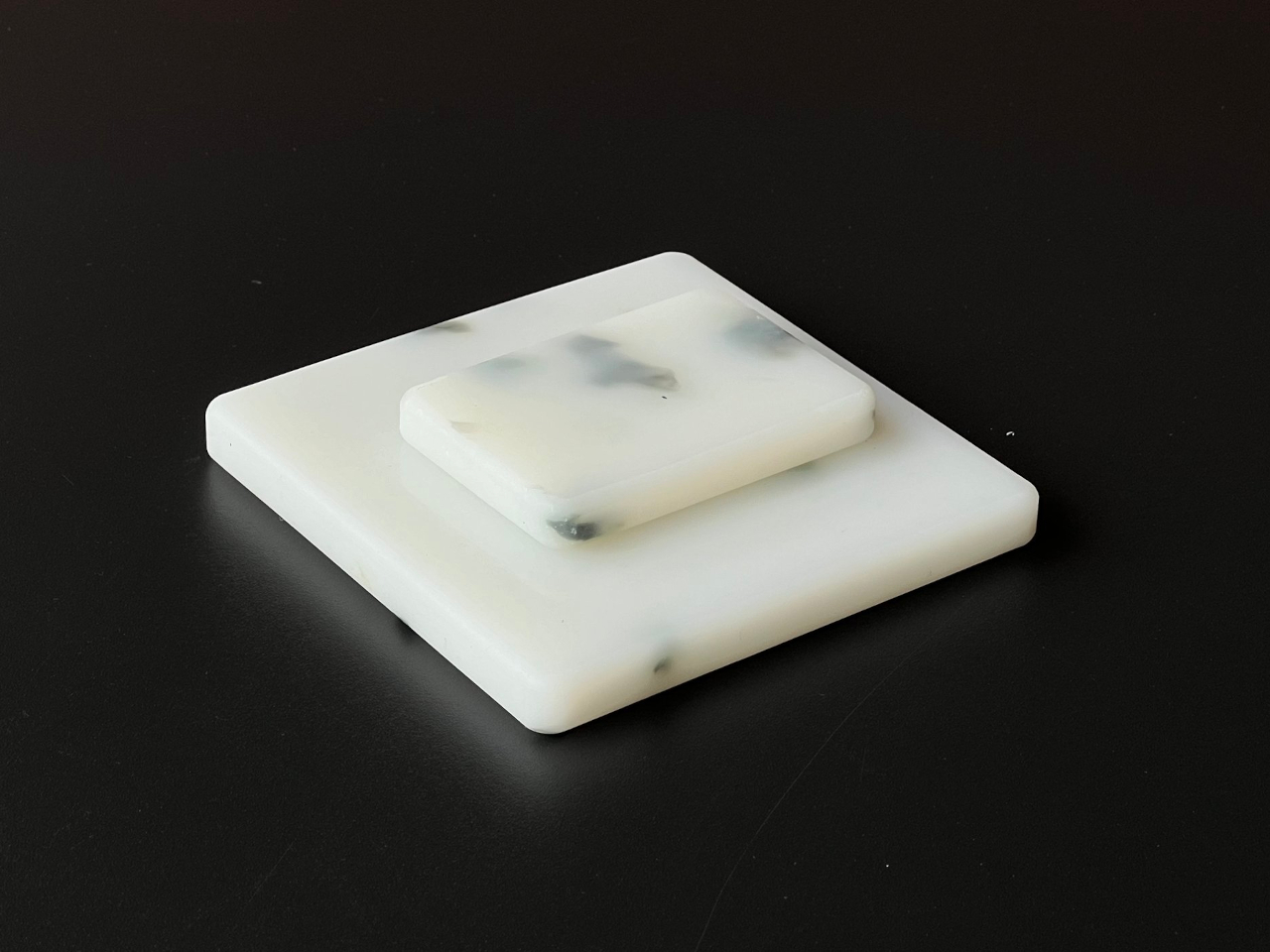

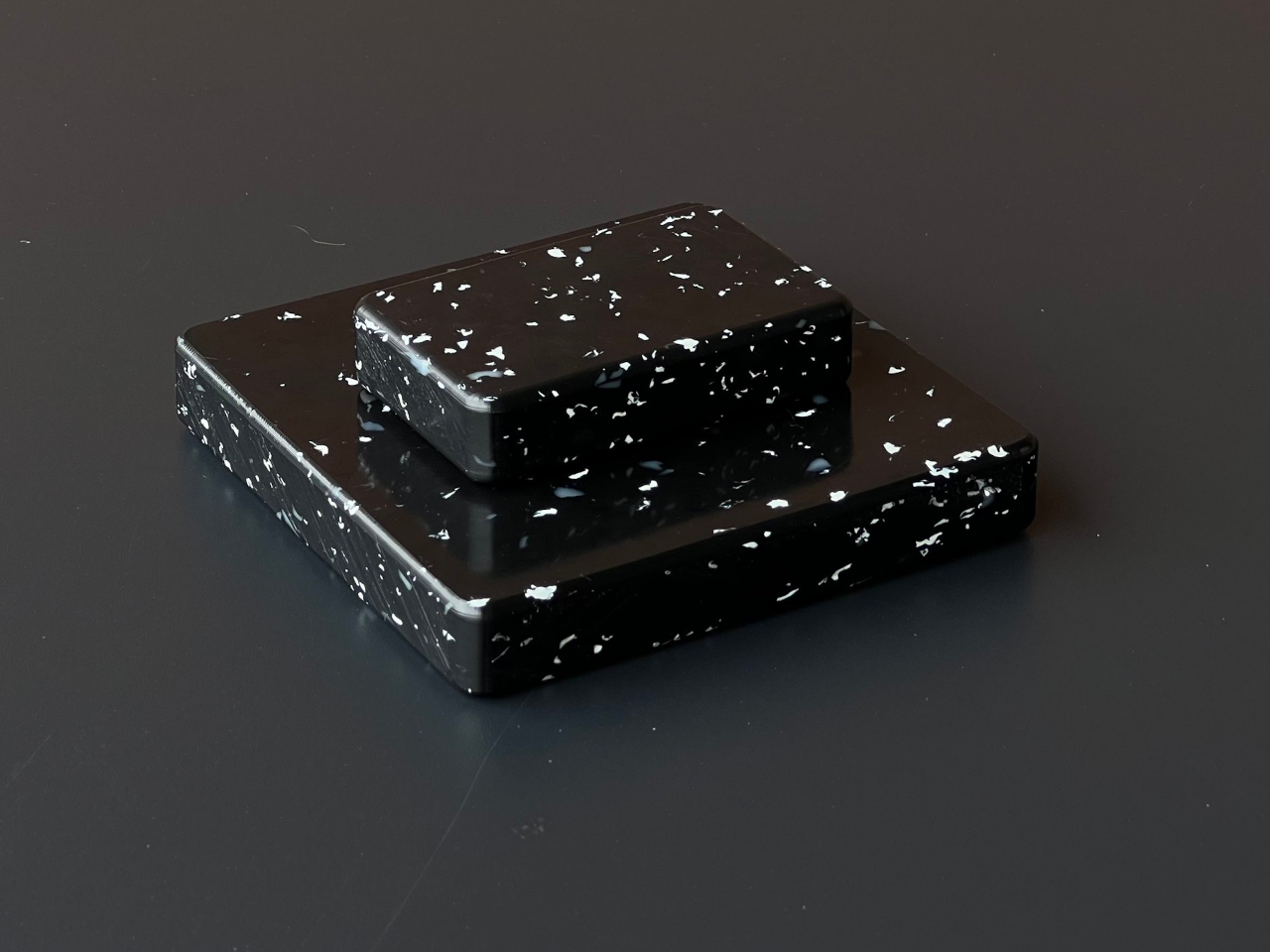

Design Declassified has developed a new kind of material that’s 100% made from recycled post-consumer and post-industrial thermoplastics without adding glue, resins, or even coloring to the mixture. This means that, after many years, the sheets can be recycled again for other purposes.

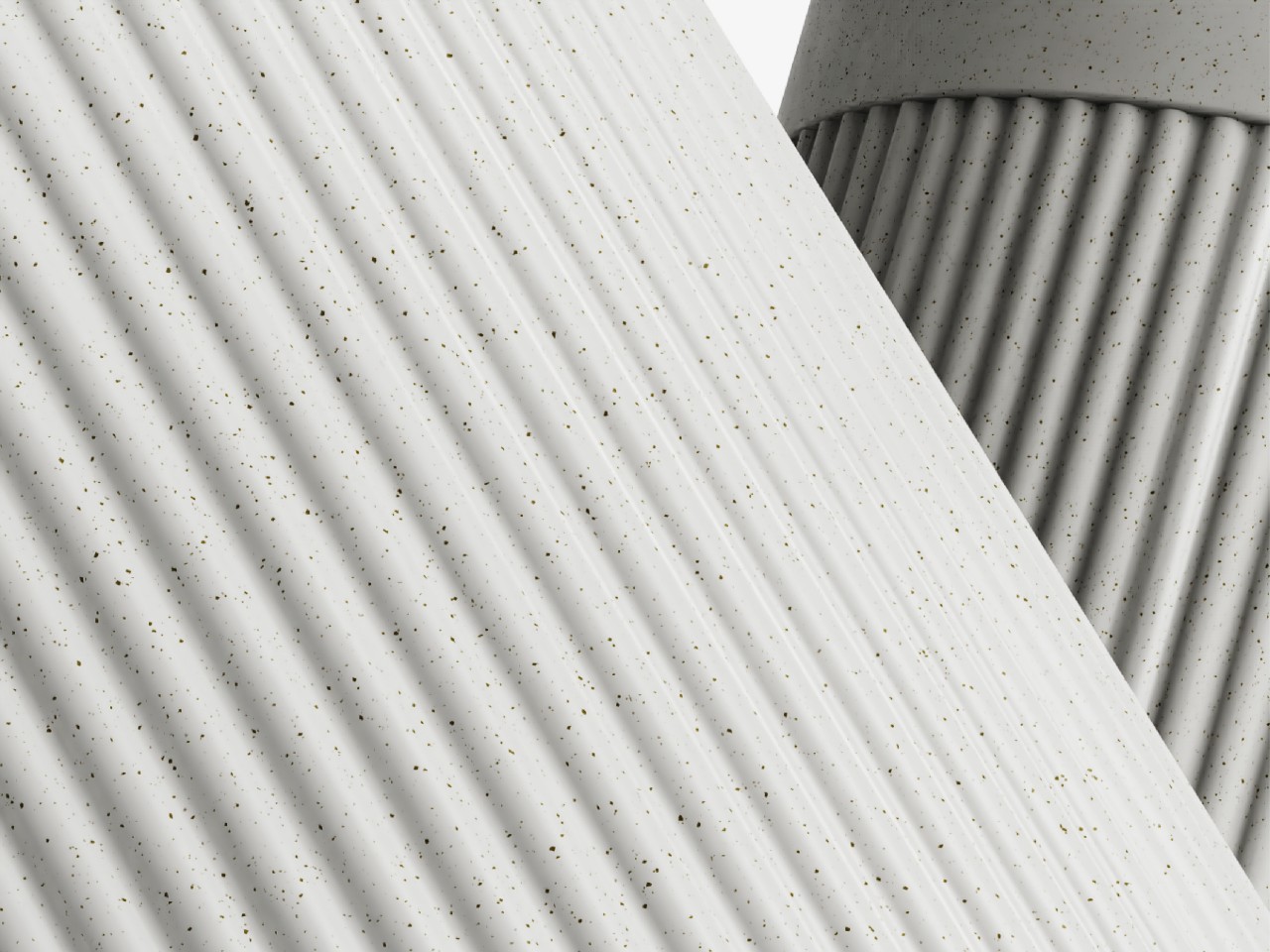

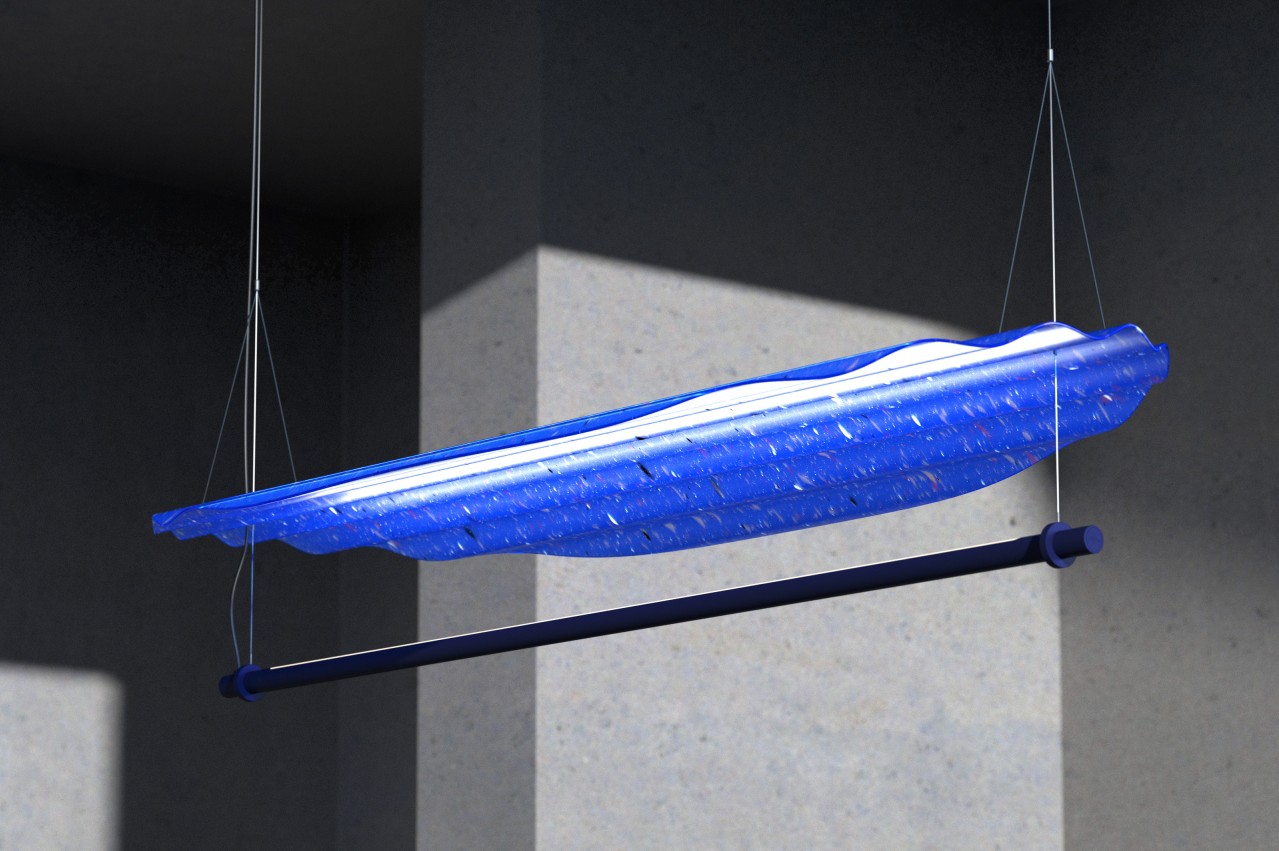

The recycled plastic sheets also come with a natural appearance not unlike marble or terrazzo, giving the material a unique character that looks nothing like your stereotypical recycled plastic. Available colors at the moment include Salt and Pepper, Moonlight, Mint, and Sea Moss, blends that you’d see in actual stone designs.

The material is durable as well, though definitely not as strong as marble or ceramic. In exchange, it retains its lightweight properties that make it easy to move around. It’s easy to cut into different shapes and forms as well, making it quite suitable for furniture like furniture, tiles for floors and walls, lighting, and even art installations.

Design Declassified is definitely an interesting solution to the plastic waste problem, especially if it can be mass-produced in an equally sustainable way. Although it doesn’t exactly reduce our reliance on plastic, it could at least help lessen the need to produce virgin plastic, especially if a more beautiful but equally versatile alternative is made available more easily.

The post Recycled plastic becomes stone-like sheets for sustainable furniture designs first appeared on Yanko Design.