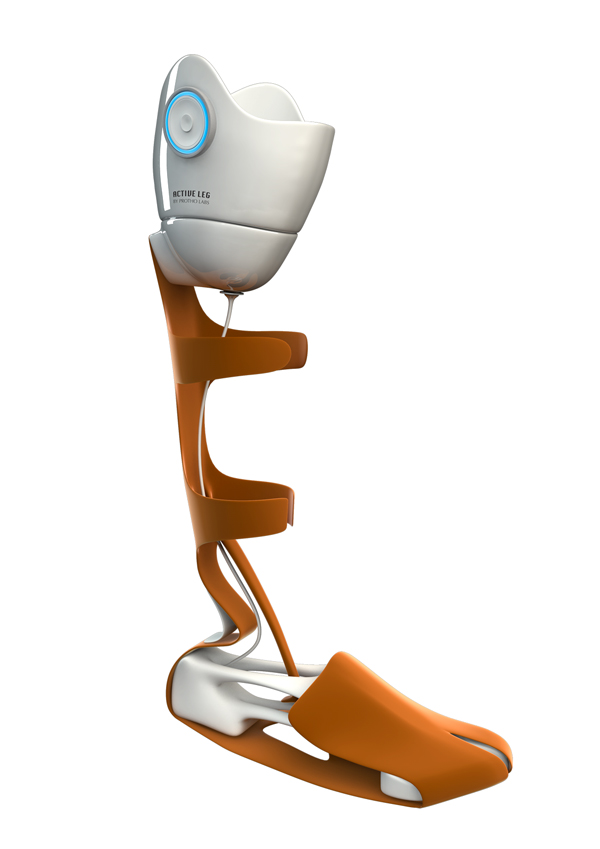

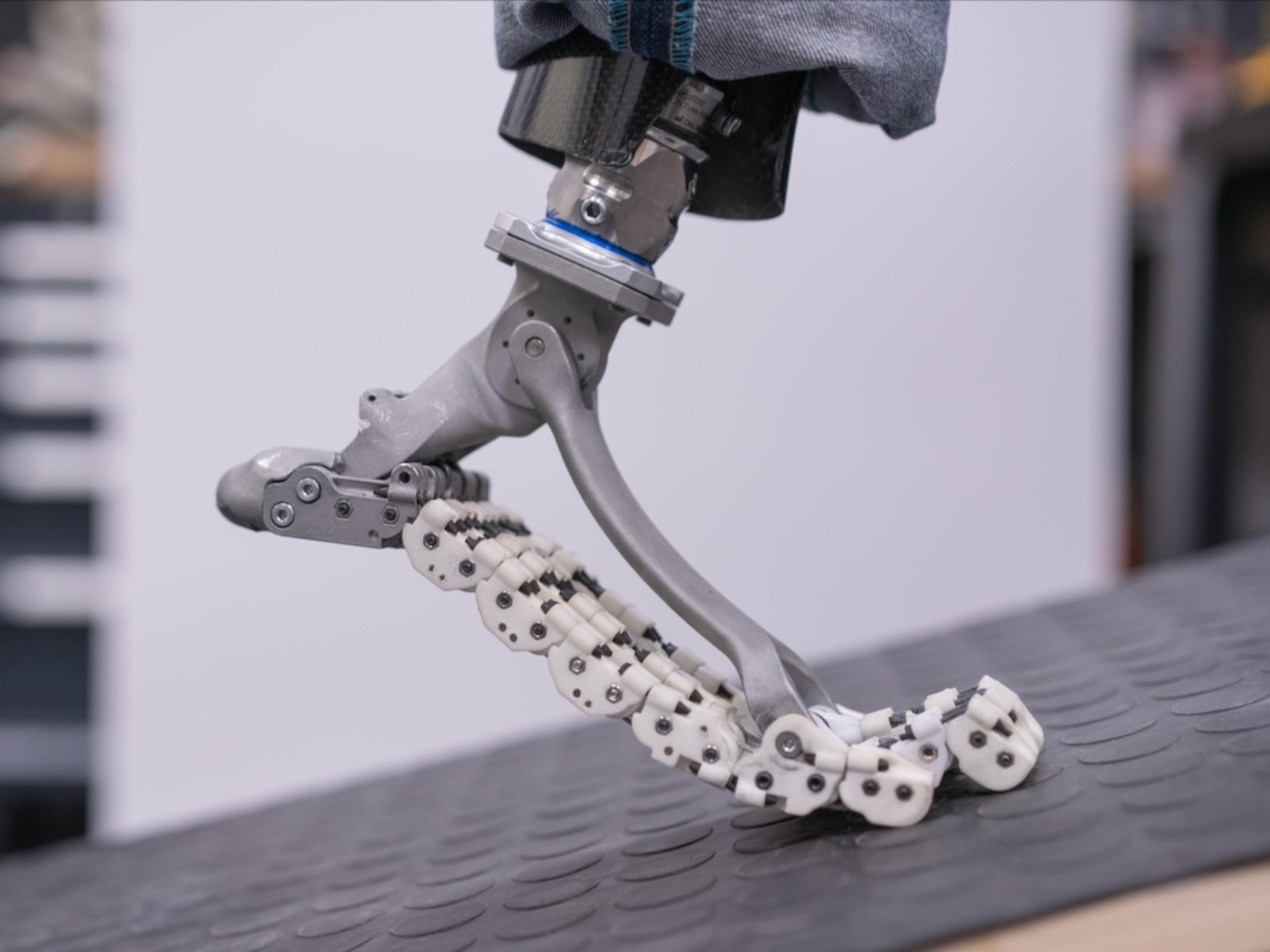

Imagine the constant challenge of navigating everyday life without the natural flexibility of your feet. This is the reality for many amputees who rely on prosthetic feet that can feel clunky and restrictive. These prosthetics often lack the ability to adapt to uneven terrain or provide the natural push-off needed for a smooth gait. However, a groundbreaking design from the Italian Institute of Technology (IIT) is poised to change the game for amputees everywhere. The SoftFoot Pro is a prototype prosthetic foot that is a literal and metaphorical leap forward in prosthetic design, mimicking the structure and movement of the human foot. Unlike conventional prosthetics that prioritize sturdiness or offer minimal flexibility, the SoftFoot Pro boasts an ingenious design that offers human-like foot flexibility and dexterity… without a single motor, servo, circuit board, or battery.

Designer: Istituto Italiano di Tecnologia

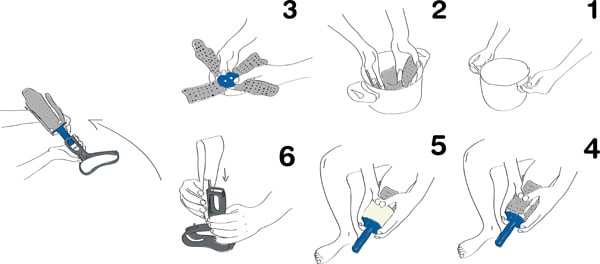

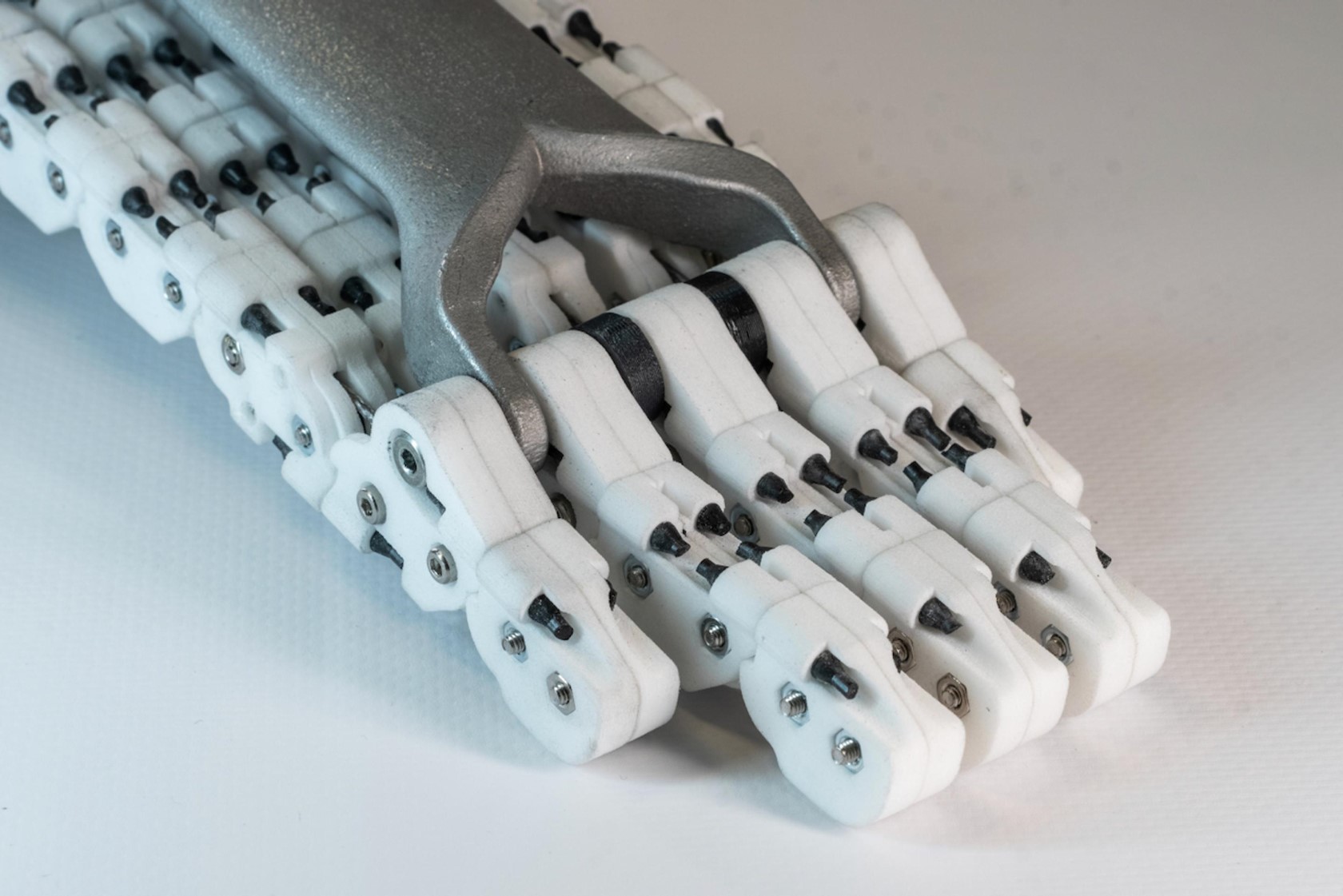

Shedding the weight and complexity of motors and electronics, the SoftFoot Pro achieves impressive functionality through a clever combination of mechanics and materials. At its core is a mobile arch mechanism, crafted from lightweight yet robust titanium or aluminum alloy. This arch connects to five parallel chains, made from high-strength plastic segments that replicate the metatarsal and phalange bones of the human foot. Elastic connectors, acting like tendons, link the segments within each chain.

The brilliance of the SoftFoot Pro lies in the details. Running through each chain is an internal steel cable that anchors to the prosthetic’s heel. This cable, along with the elastic connectors, mimics the plantar fascia – the band of tissue in the human foot that stores and releases energy with each step. This ingenious design allows the SoftFoot Pro to absorb impact, propel the user forward with a natural push-off, and even conform to uneven surfaces. This enhanced flexibility translates to greater stability and a more natural gait for users.

Weighing in at a mere 450 grams (1 pound), the SoftFoot Pro is incredibly lightweight despite its ability to support users weighing up to 100 kg (220 lbs). Initial trials conducted at Hannover Medical School and the Medical University of Vienna have yielded promising results. Amputees who participated in the trials experienced a significant improvement in their gait, with increased balance and a more natural walking experience on various terrains.

The applications of the SoftFoot Pro extend beyond human users. Researchers have also successfully tested the design on robots, including the Anymal quadruped robot and the HRP-4 humanoid robot. This versatility highlights the potential of this design to revolutionize not just prosthetics but also the field of robotics.

The post Revolutionary Prosthetic Foot achieves human-level flexibility and grip without motors or electronics first appeared on Yanko Design.