Of the many pieces of clothing we buy and use, shoes are probably the ones designed to last the longest. Because of that, footwear is usually made using materials that are durable and long-lasting but are also unfortunately often not environment-friendly. Rubber, particularly synthetic rubber, is one of the biggest culprits, not just in terms of post-consumer waste but even material waste during the manufacturing process. As one of the biggest footwear makers, Nike is thankfully taking a responsible stance, giving those rubber byproducts and excess materials a new purpose.

Designer: Nike

Although natural rubber is sourced from plants, it’s not that easy to replenish to meet the high demand for the material. Just like plastic, synthetic rubber is easy to manufacture but also harmful the environment due to their chemical content. Rubber from discarded shoes is one thing, but even the bits and pieces of cutoffs and scraps produced when making them also pose a threat to the environment.

Considering its lion’s share of the sports shoes market, Nike developed the Grind material that recycles manufacturing byproducts like rubber, foam, and even textiles to create a material that can be applied to products other than shoes. In this case, the Nike Grind Dumbbells are made with at least 20% Nike Grind material to offer an alternative fitness tool for environment-conscious consumers.

In addition to its sustainable value, the recycled material also gives the dumbbells a unique aesthetic. The hexagonal weights themselves have a light gray hue sprinkled with colorful specs that create a terrazzo-like appearance. Each dumbbell is, thus, totally unique, and the mixture of colors will vary from season to season, depending on the styles of footwear that Nike launches.

The gray motif of the weights perfectly complements the chrome-plated knurled handles. The handle diameter varies depending on the weight, increasing as the load gets heavier to provide a more ergonomic grip. Available in weights ranging from 2.5 lbs to 50 lbs, the Nike Grind Dumbbell offers people a fitness tool that not only takes care of their health but also the environment.

The post Nike Grind Dumbbells use recycled rubber from footwear byproduct first appeared on Yanko Design.

Shoes will invariably wear out with enough use, but scientists might have found a way to delay the shopping trip for their replacements. A USC team has created a self-healing 3D-printed rubber that could be ideal for footwear, tires and even soft ro...

Shoes will invariably wear out with enough use, but scientists might have found a way to delay the shopping trip for their replacements. A USC team has created a self-healing 3D-printed rubber that could be ideal for footwear, tires and even soft ro...

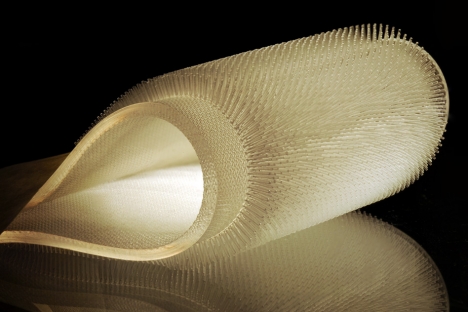

Large oceangoing creatures, like whales and seals, keep warm with thick layers of blubber. But smaller mammals like beavers and otters have a different method of insulation: Their dense fur, which traps warm air bubbles to separate their body from co...

Large oceangoing creatures, like whales and seals, keep warm with thick layers of blubber. But smaller mammals like beavers and otters have a different method of insulation: Their dense fur, which traps warm air bubbles to separate their body from co...

Having to scrape ice off your windshield in freezing temperatures before heading off to work is awful. When ice builds up on airplanes and other equipment, it can go from being a nuisance to causing serious danger. To combat icy buildup, researchers...

Having to scrape ice off your windshield in freezing temperatures before heading off to work is awful. When ice builds up on airplanes and other equipment, it can go from being a nuisance to causing serious danger. To combat icy buildup, researchers...

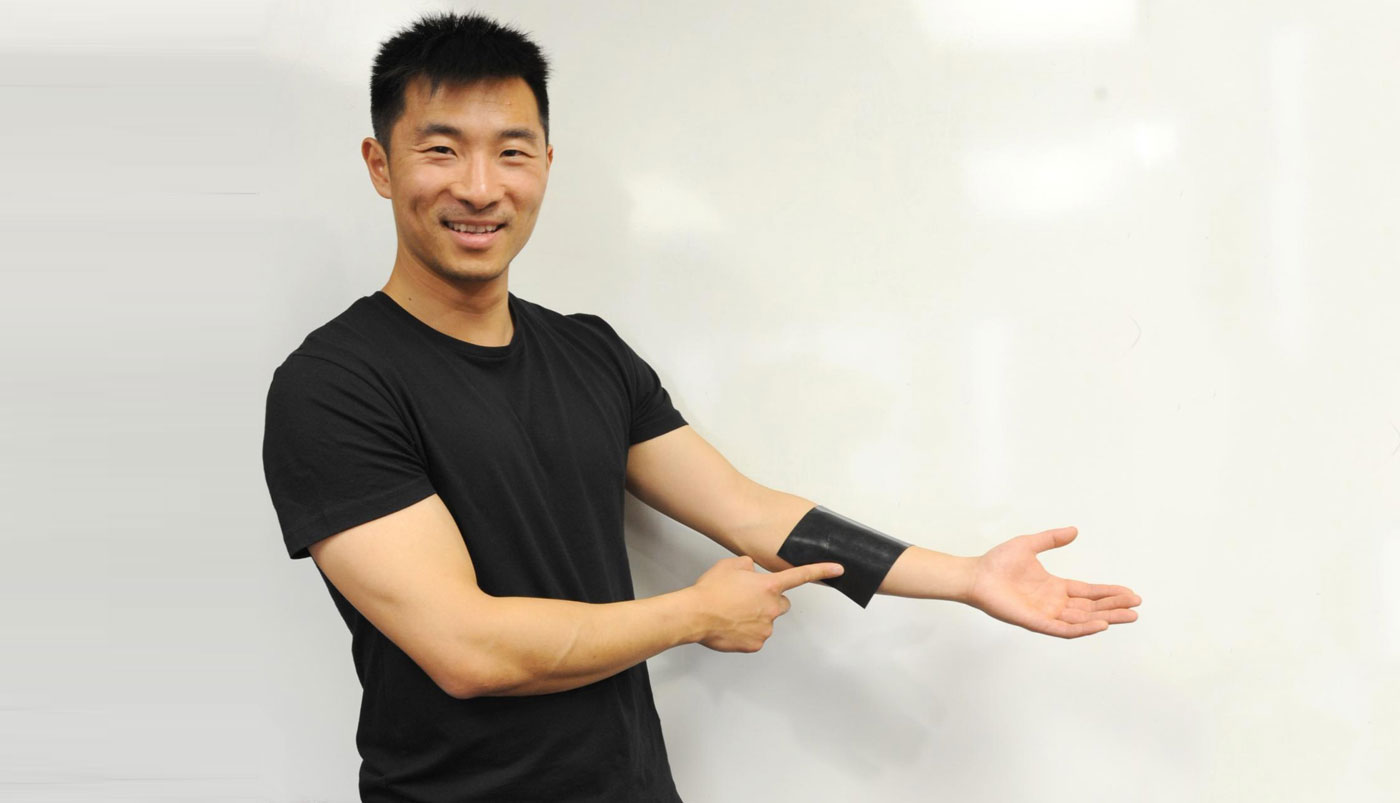

There's a whole branch of science that's dedicated to turning flexible surfaces into sensors that can be used as an artificial substitute for skin. These materials could then be used to give robots a sense of touch, or even to restore feeling for peo...

There's a whole branch of science that's dedicated to turning flexible surfaces into sensors that can be used as an artificial substitute for skin. These materials could then be used to give robots a sense of touch, or even to restore feeling for peo...