Isn’t it ironic when we say space is infinite, yet it has the same housing problem we face on Earth of not having enough room? The challenge for builders of space habitats is not the vastness of space itself but the constraints of shipping capacity. Despite the increased frequency and reduced cost of rocket launches, the amount of building material that can be sent into orbit remains limited. The International Space Station (ISS), for example, required over 40 flights and cost more than $100 billion to construct. In contrast, Max Space is giving more in less! A bargain that can never go wrong. It is a company revolutionizing space habitation by offering equivalent cubic volume to the ISS for just $200 million, including launch, slashing costs by over a hundred-fold.

Designer: Max Space

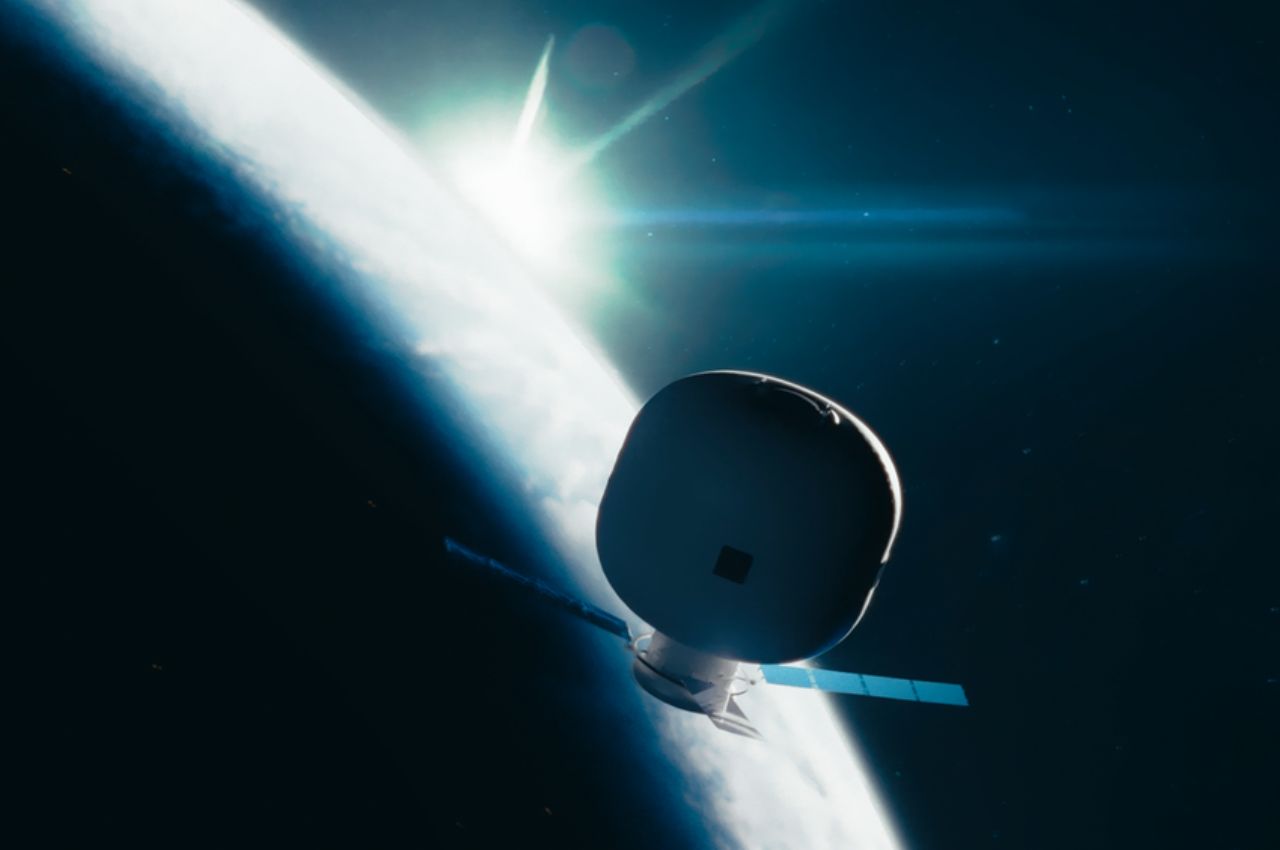

Max Space was founded by Maxim de Jong, a pioneer in “soft system space architecture.” De Jong is globally recognized as the foremost expert in utilizing expandable materials for space. His early designs, Genesis I and Genesis II, have been orbiting Earth since 2006 and 2007. Max Space’s approach is distinguished by its use of ‘isotensoid’ architecture. This innovative design ensures that every structural fiber remains unencumbered, allowing it to assume an ideal geometry for optimal load-bearing capability. This results in the lowest possible mass and cost while offering unsurpassed predictability and unlimited scalability.

A significant advantage of Max Space’s inflatable modules is their enhanced resilience against space debris. Unlike traditional hard modules made of aluminum and titanium, Max Space’s expandable modules feature a multi-layered system of fiber-based ballistic shielding. This design provides greater resilience, making the material safer and stronger.

The Max Space 20, the company’s initial module, provides 20 cubic meters (706 cubic feet) of interior space. Though smaller than the ISS’s habitable volume of 388 cubic meters (13,696 cubic feet), it marks a significant step towards larger structures. The company plans to launch the Max Space 20 units in 2026, followed by the Max Space 100 and Max Space 1000 within the next four years. The Max Space 1000 will dwarf the ISS in volume, illustrating the company’s commitment to scalability.

“More volume, less cost” is Max Space’s motto. Their first expandable module, scheduled to launch on a SpaceX rideshare mission in 2025, will be compacted into two cubic meters for launch and expand to 20 cubic meters after deployment. This will make it the largest expandable module flown to date. Aaron Kemmer, co-founder and CEO of Max Space, drew on his experience at Made In Space, a company that developed 3-D printers for the ISS, to address the volume bottleneck in space habitats. His vision is to overcome the limitations of confined space, which often hinder meaningful projects.

Max Space’s expandable module technology builds on the legacy of Bigelow Aerospace’s Genesis 1 and 2 and BEAM. However, Max Space’s approach differs significantly. Instead of a bi-directional “basket weave” fabric structure, which distributes load unpredictably, Max Space employs a technology that distributes loads in one direction. This ultra-high-performance vessel, a serendipitous discovery by de Jong, ensures more precise safety margins and scalability. Tests have shown that the modules can burst at pressures within 10% of predicted levels, demonstrating excellent predictability.

Recently, Max Space showcased a test version of the Max Space 20 module at the MARS Conference, hosted by Jeff Bezos. The company is now developing a flight version with enhanced debris shielding. The scalability of this design will enable Max Space to quickly advance to modules with volumes of 100 to 1,000 cubic meters, equivalent to the entire ISS volume, at a fraction of the cost.

Max Space does not intend to build its own space station but aims to supply modules to other commercial space station developers, including those involved in NASA’s Commercial Low Earth Orbit Development (CLD) program. The company remains focused on its core technology, contracting out other elements like power, propulsion, and life support systems.

Having raised a “sub-$10 million” seed round, Max Space is developing its first module and preparing for its rideshare launch. With a small team of less than a dozen employees, the company is committed to scaling up efficiently and cost-effectively.

Future commercial space stations are a prime application for Max Space’s modules. Aaron Kemmer emphasized the potential for these space habitats to revolutionize fields such as in-space manufacturing, biosciences, and pharmaceuticals by providing affordable and scalable solutions. Initially, the modules may serve government agencies as in-space propellant depots or storage facilities, with the company prioritizing the demonstration of safety and functionality before accommodating human habitation.

The potential applications for Max Space’s habitats are vast, ranging from orbiting research and manufacturing facilities to lunar surface installations. Imaginative possibilities include space tourism and zero-G sports. Additionally, these habitats could enable nations without a domestic space program to establish an orbital presence, significantly broadening global participation in space exploration and utilization.

The post Max Space Is Revolutionizing Balloon-Like Scalable Space Habitats for a New Era in Space Exploration first appeared on Yanko Design.

The ongoing NASA privatization push just reached an important milestone. The administration has chosen Axiom Space to supply its first commercial destination module for the International Space Station. The habitable module will connect to the stati...

The ongoing NASA privatization push just reached an important milestone. The administration has chosen Axiom Space to supply its first commercial destination module for the International Space Station. The habitable module will connect to the stati...

India's broadening spaceflight ambitions now include a longer-term presence in Earth's orbit. Indian Space Research Organization chief K Sivan (above) recently revealed plans to launch a space station around 2030. It will be a relatively small stat...

India's broadening spaceflight ambitions now include a longer-term presence in Earth's orbit. Indian Space Research Organization chief K Sivan (above) recently revealed plans to launch a space station around 2030. It will be a relatively small stat...

Many video games are set in space. Most cast you as a human super-soldier or plucky science-type trying to untangle a truly terrible situation. Not Observation. The latest game from No Code, the Scottish studio behind Stories Untold, makes you play a...

Many video games are set in space. Most cast you as a human super-soldier or plucky science-type trying to untangle a truly terrible situation. Not Observation. The latest game from No Code, the Scottish studio behind Stories Untold, makes you play a...

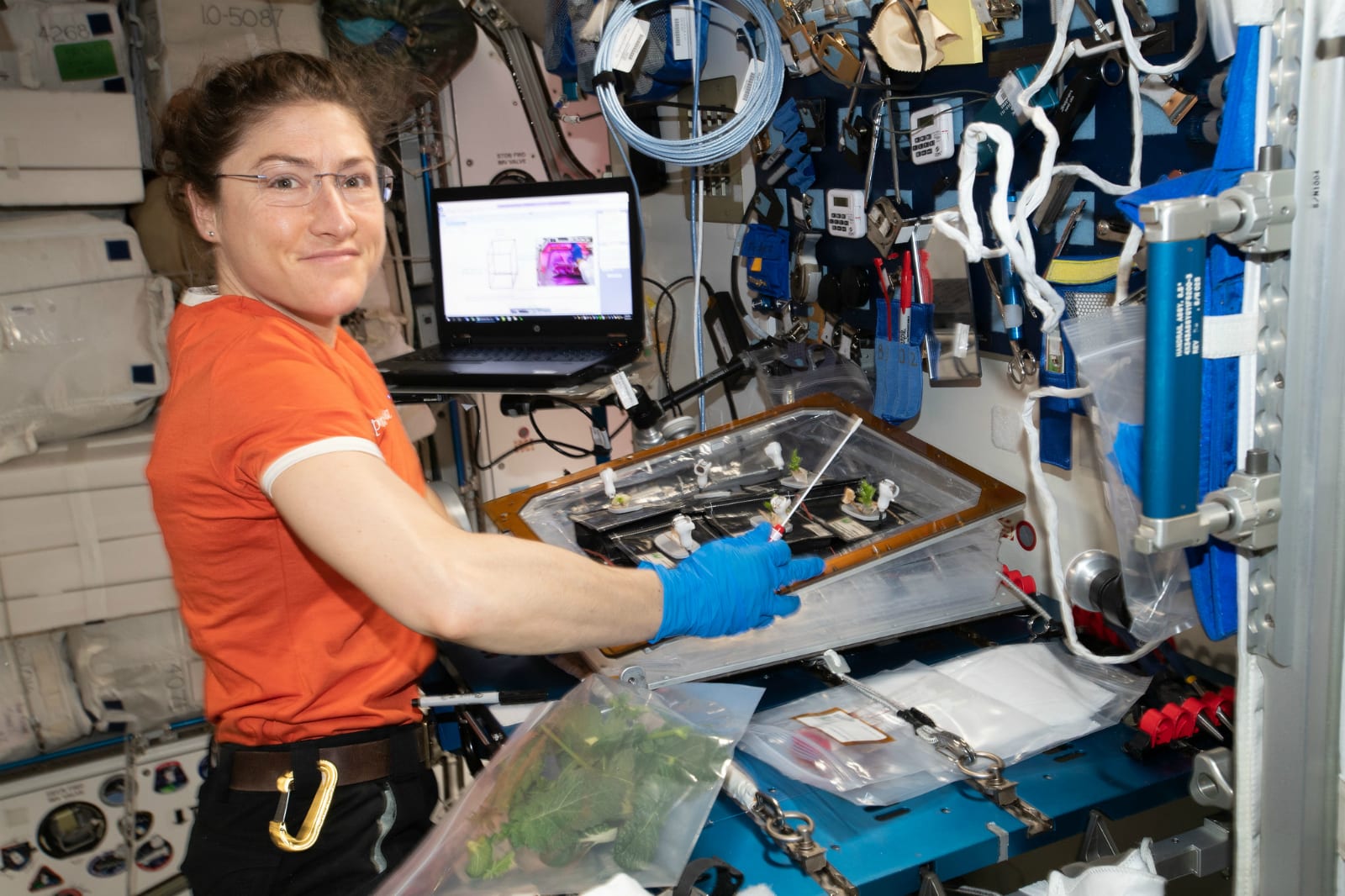

Thanks to NASA's recent schedule changes, astronaut Christina Koch will soon hold the record for the longest space flight by a woman. Koch arrived at the International Space Station on March 14 and has already conducted one spacewalk. She'll now rema...

Thanks to NASA's recent schedule changes, astronaut Christina Koch will soon hold the record for the longest space flight by a woman. Koch arrived at the International Space Station on March 14 and has already conducted one spacewalk. She'll now rema...